ISO9001 2015 Prototype Injection Molding For Customized Manufacturing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Runner System | Cold Runner/Hot Runner | Mould Test | 100% Inspection Before Shipment |

|---|---|---|---|

| Mould Base | LKM, HASCO, Etc. | Mould Standard | DME, HASCO, Etc. |

| Color | Customized | Certificate | ISO9001:2015 |

| Mould Process | Injection Moulding | Lead Time | 30-45 Days |

| High Light | ISO Prototype Injection Molding,Prototype Injection Molding Customized |

||

Product Description:

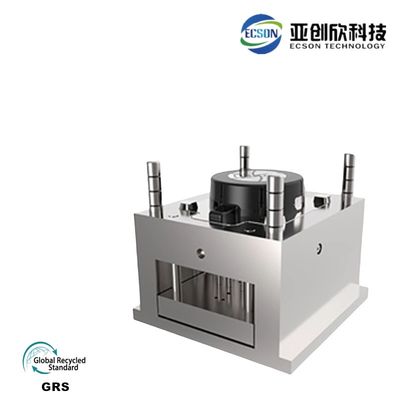

The Home Appliance Mould is a premium product that caters to the ever-growing demands of the manufacturing sector, specifically designed to shape and create various components for home appliances. At the core of our operations, we leverage advanced design software such as UG, ProE, and CAD, which are instrumental in the meticulous design and precision engineering of our moulds. These powerful tools enable our skilled designers to craft complex moulds that meet the customized requirements of our clients, ensuring a perfect fit for the intended appliance part every single time.

Our Home Appliance Mould is crafted from high-grade plastic materials, selected for their durability, stability, and capacity to withstand the rigors of the manufacturing process. The plastic material not only ensures the longevity of the mould but also guarantees that the final product has a clean, professional finish. This is particularly important in the home appliance sector, where aesthetics go hand in hand with functionality. The mould's robust construction enables it to deliver consistent results, ensuring that each component produced is of the highest quality.

Quality assurance is at the forefront of our manufacturing ethos. Each Home Appliance Mould undergoes a rigorous 100% inspection before shipment. This thorough testing protocol is designed to detect any imperfections or inconsistencies that could impact the performance or appearance of the moulded appliance parts. Our commitment to meticulous testing ensures that our clients receive only the best products, reducing the likelihood of production downtime due to mould defects.

Regarding surface finish, the Home Appliance Mould boasts an exceptional polishing process that contributes to the visual appeal and functional performance of the final product. A polished surface minimizes friction and facilitates the easy release of the part from the mould, reducing wear and tear on both the mould and the produced parts. This attention to surface finish is a testament to our dedication to providing moulds that not only meet but exceed industry standards.

Adhering to mould standards is essential for ensuring interoperability and ease of integration within the production line. Our Home Appliance Mould is designed to conform to recognized industry standards, including DME, HASCO, and others. This adherence to standards ensures that our moulds are compatible with a wide range of production equipment and can be seamlessly incorporated into existing manufacturing systems, providing our clients with flexibility and ease of use.

One of the standout applications of our Home Appliance Mould is in the fabrication of air cooler components. The air cooler mould is a specialized product that demands precision and reliability, as air coolers are essential appliances in many households, especially in warmer climates. Our air cooler mould is engineered to produce parts that are robust, efficient, and fit perfectly within the air cooler assembly. With repeated emphasis on the air cooler mould within our product range, we assure our clients of our expertise and specialization in this particular type of mould, ensuring that the produced air cooler components are of the highest quality and ready for assembly and use.

In conclusion, our Home Appliance Mould represents the pinnacle of mould manufacturing. It combines advanced design software, premium materials, rigorous testing, exceptional surface finishing, and strict adherence to industry standards. Whether it is an air cooler mould or any other home appliance component, our moulds are designed to deliver unparalleled performance and reliability. Choose our Home Appliance Mould for your manufacturing needs and experience the difference in quality and efficiency that our product brings to the table.

Features:

- Product Name: Home Appliance Mould

- Design Software: UG, ProE, CAD, etc.

- Mould Test: 100% Inspection Before Shipment

- Surface Finish: Polishing

- Cavity Number: Multi-cavity

- Color: Customized

- Keywords: Air Cooler Mould, Air Cooler Mould, Air Cooler Mould

Technical Parameters:

| Technical Parameter | Description |

|---|---|

| Mould Life | 500,000 Shots |

| Lead Time | 30-45 Days |

| Cavity Number | Multi-cavity |

| Mould Process | Injection Moulding |

| Runner System | Cold Runner/Hot Runner |

| Material | Plastic |

| Color | Customized |

| Mould Standard | DME, HASCO, Etc. |

| Design Software | UG, ProE, CAD, Etc. |

| Mould Base | LKM, HASCO, Etc. |

Applications:

The ecson brand, hailing from the bustling industrial city of Xiamen, China, is at the forefront of providing precision home appliance moulds that cater to a wide range of applications and scenarios. With the burgeoning demand for high-quality air cooling solutions, the air cooler mould from ecson has become a critical component in the manufacturing of efficient and reliable air coolers. Whether it is for residential, commercial, or industrial settings, the versatility of the ecson air cooler mould is evident in its widespread use.

The design of each air cooler mould is meticulously crafted using advanced design software such as UG, ProE, and CAD, ensuring that each mould meets the exact specifications required for producing air coolers of various sizes and capacities. The customizability of the ecson moulds is a testament to their adaptability in creating air coolers that fit into different environments and meet diverse cooling requirements.

One of the hallmarks of the ecson air cooler mould is its exceptional surface finish. Achieved through high-grade polishing processes, the moulds ensure that the final product not only functions optimally but also has an aesthetically pleasing appearance. Customization does not end with the size and shape; clients can also request specific colors to align with their brand identity or to match the decor where the air cooler will be placed.

Quality is never compromised with ecson products. Each air cooler mould is manufactured under the stringent guidelines of the ISO9001:2015 certification. This certification underscores the commitment to quality and consistency that is synonymous with the ecson brand. The air cooler moulds produced under these standards ensure that air coolers manufactured using these moulds are reliable, durable, and meet international quality standards.

In terms of application, the ecson air cooler mould is suitable for use in a variety of scenarios. During the sweltering summer months, air coolers crafted from these moulds provide much-needed relief in homes, offices, and large commercial spaces. In regions where air conditioning is not practical or economically feasible, air coolers made from the ecson air cooler mould offer an energy-efficient alternative. Furthermore, in outdoor events or in areas where temporary cooling solutions are required, portable air coolers manufactured using these moulds can be easily deployed.

Overall, the ecson air cooler mould is an indispensable tool in the home appliance industry, enabling the creation of products that bring comfort and convenience to people's lives across various settings. Reflecting innovation, customization, and a dedication to quality, ecson continues to set the standard for mould manufacturing in the air cooler market.

Customization:

Brand Name: ecson

Place of Origin: china xiamen

Design Software: UG, ProE, CAD, etc.

Mould Life: 500,000 Shots

Mould Process: Injection Moulding

Size: Customized

Mould Base: LKM, HASCO, etc.

Our ecson home appliance moulds are expertly designed using advanced software like UG, ProE, and CAD to cater to your specific needs. Originating from china xiamen, our moulds guarantee a long service life of up to 500,000 shots. We specialize in air cooler moulds, ensuring each air cooler mould is crafted through precision injection moulding. Our custom size approach means your air cooler mould will be tailored exactly to your requirements, supported by industry-standard bases like LKM and HASCO.

Support and Services:

Our Home Appliance Mould product comes with comprehensive technical support and services designed to ensure maximum satisfaction and seamless operation. Our team of experts is dedicated to providing you with the assistance you need to get the most out of your moulds. We offer a range of services including:

Installation Guidance: Detailed instructions for the correct installation of your Home Appliance Mould, ensuring that it fits perfectly with your production requirements.

Product Training: Customized training sessions to help your staff understand the functionality and maintenance of the moulds, aimed at optimizing performance and extending mould life.

Maintenance Support: Advice on the best practices for maintaining your Home Appliance Mould, including cleaning, storage, and part replacement schedules.

Troubleshooting: Rapid response to any operational issues you might encounter. Our technical team is skilled in diagnosing and resolving problems quickly, minimizing downtime.

Upgrades and Updates: Information on the latest upgrades and updates available for your moulds to keep them running efficiently and to take advantage of the latest innovations in mould technology.

Replacement Parts: We provide high-quality replacement parts for any components that may wear out over time, ensuring that your mould remains in top working condition.

Our goal is to provide exceptional service and support that matches the quality of our Home Appliance Moulds. Please consult your product documentation for specific instructions on how to access these services.

Packing and Shipping:

Product Packaging for Home Appliance Mould:

Our Home Appliance Moulds are securely packaged to ensure they arrive at their destination in pristine condition. Each mould is encased in a protective layer of bubble wrap or foam to cushion against impacts during transit. Following this, the mould is placed within a sturdy, corrugated cardboard box which is tailored to the mould's dimensions, preventing unnecessary movement. For additional security, the box is sealed with industrial-strength tape and labeled with 'Fragile' to encourage careful handling.

Shipping Information for Home Appliance Mould:

We take great care in shipping our Home Appliance Moulds. All shipments are dispatched through our trusted logistics partners who specialize in the safe conveyance of industrial goods. Upon dispatch, customers receive a tracking number to monitor their package's progress. We offer various shipping options to meet different timelines and budget requirements, including standard, expedited, and express shipping. Please note that shipping times may vary depending on the destination and customs clearance processes for international deliveries.

FAQ:

Q1: What types of home appliance moulds does ecson offer?

A1: ecson offers a wide range of home appliance moulds, including but not limited to moulds for plastic parts of air conditioners, refrigerators, washing machines, microwaves, and other small electrical appliances. Each mould is designed to meet industry standards and client specifications.

Q2: Can I get a custom mould design for a specific home appliance part from ecson?

A2: Yes, ecson specializes in custom mould designs. You can collaborate with our design team to create a mould that fits your exact requirements. We utilize advanced CAD/CAM/CAE systems to ensure the precision and quality of our custom moulds.

Q3: What materials are used in the construction of ecson home appliance moulds?

A3: ecson home appliance moulds are made from high-quality steel and other durable materials that are selected based on the mould's specific application and the customer's needs. We ensure that all materials used can withstand the rigors of the moulding process and prolong the life of the mould.

Q4: How does ecson ensure the quality of its home appliance moulds?

A4: ecson follows strict quality control procedures throughout the manufacturing process. From the initial design to the final inspection, each mould is subjected to rigorous testing to ensure it meets our high standards of quality and performance. We also use precision machining and advanced technologies to achieve the best possible results.

Q5: What is the lead time for receiving a home appliance mould from ecson?

A5: The lead time for a home appliance mould can vary depending on the complexity of the design and the current production schedule. However, we strive to work efficiently to meet our clients' timelines. It's best to contact us directly with specific details about your project for a more accurate estimate of the lead time.