ISO9001 2015 Certified DME Standard Air Cooler Mould With Tent Tacks

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Finish | Polishing | Lead Time | 30-45 Days |

|---|---|---|---|

| Mould Test | 100% Inspection Before Shipment | Mould Process | Injection Moulding |

| Design Software | UG, ProE, CAD, Etc. | Color | Customized |

| Mould Standard | DME, HASCO, Etc. | Mould Life | 500,000 Shots |

| High Light | ISO Air Cooler Mould,Air Cooler Mould With Tent Tacks |

||

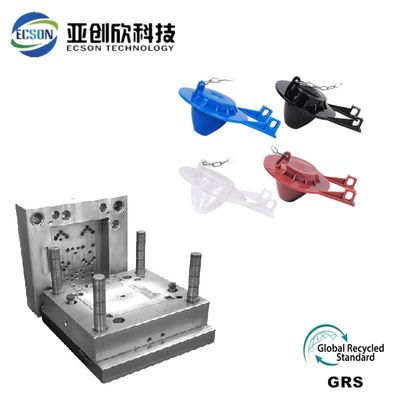

Product Description:

The Home Appliance Mould is an essential component in the manufacturing of high-quality air coolers. Engineered with precision and care, this mould is designed to meet the rigorous standards of today's appliance industry, ensuring that each product is both durable and aesthetically pleasing. Our Home Appliance Mould is built to the exacting specifications of mould standards such as DME and HASCO, which are recognized internationally for their quality and reliability. This ensures that our moulds are compatible with a wide range of production systems and can be easily integrated into any manufacturing process.

One of the most critical aspects of a mould is its surface finish, and our Home Appliance Mould boasts a surface that has been polished to perfection. This attention to detail not only enhances the appearance of the final product but also contributes to the efficiency of the moulding process by allowing for easy release of the finished air cooler components. The superior polishing also helps in minimizing maintenance and cleaning time, which is crucial in a high-volume production environment, where downtime can be costly.

At the foundation of our Home Appliance Mould is the robust mould base, and we offer options from trusted names such as LKM and HASCO. These bases provide the structural integrity necessary for the mould to withstand the pressures of injection moulding, ensuring a consistent and precise production of air cooler components. The mould base also plays a pivotal role in the longevity of the mould, as it is designed to resist wear and tear, thereby extending the life of the mould and reducing the need for frequent replacements.

Understanding the need for versatility in production, our Home Appliance Mould features multi-cavity design. This allows for the simultaneous manufacture of multiple components, dramatically increasing output and efficiency. The multi-cavity approach is particularly beneficial for large-scale production runs, as it enables manufacturers to meet high demand without sacrificing quality. Each cavity is crafted to exact dimensions to ensure uniformity across all produced parts, which is vital for the assembly of the final air cooler product.

To complement the multi-cavity design, our Home Appliance Mould incorporates a sophisticated runner system, which can be configured as either a cold runner or a hot runner, depending on the specific needs of the production. The cold runner system is highly cost-effective and is often used for simpler part designs, whereas the hot runner system, although more complex, can reduce waste and improve cycle times. Both systems are designed to streamline the flow of plastic to each cavity, ensuring consistent quality and minimizing the risk of defects in the air cooler moulding process.

Our commitment to delivering a top-tier Home Appliance Mould is evident in every aspect of the product, from the standard-compliant mould design to the smooth and polished finish that defines each air cooler mould. The robust mould base options, paired with the flexibility of multi-cavity configurations and both cold and hot runner systems, make our mould an indispensable tool for manufacturers seeking to produce high-quality air cooler components. With our Home Appliance Mould, you can expect a product that not only meets industry standards but also exceeds them, providing a reliable and efficient solution for your air cooler mould needs.

Features:

- Product Name: Home Appliance Mould

- Lead Time: 30-45 Days

- Certificate: ISO9001:2015

- Size: Customized

- Material: Plastic

- Mould Base: LKM, HASCO, etc.

- Keywords: air cooler mould, air cooler mould, air cooler mould

Technical Parameters:

| Attribute | Detail |

|---|---|

| Mould Life | 500,000 Shots |

| Mould Base | LKM, HASCO, Etc. |

| Cavity Number | Multi-cavity |

| Material | Plastic |

| Size | Customized |

| Design Software | UG, ProE, CAD, Etc. |

| Certificate | ISO9001:2015 |

| Mould Test | 100% Inspection Before Shipment |

| Runner System | Cold Runner/Hot Runner |

| Color | Customized |

Applications:

The ecson brand, originating from the industrious city of Xiamen, China, has firmly established itself in the realm of home appliance manufacturing with its top-tier home appliance moulds. These moulds are not just another accessory in the production line; they are the cornerstone for crafting reliable and high-quality air coolers. The application occasions and scenarios for ecson's air cooler mould span across a variety of settings, where the customization and precision provided by their products are in high demand.

Ecson's home appliance moulds are tailored to meet the specific requirements of the manufacturers, thanks to their customized sizing options. This ensures that each air cooler mould is optimized for the particular model of air cooler being produced, whether it be for residential, commercial, or industrial applications. The multi-cavity design of ecson moulds amplifies productivity, allowing manufacturers to scale up their production to meet the seasonal spikes in demand for air coolers, especially in the warmer months.

The mould process utilized by ecson's products is the injection moulding technique. This process is renowned for its efficiency and ability to produce components with intricate details and superior structural integrity. In the case of air cooler moulds, this means that each part produced is a testament to precision engineering, contributing to the overall effectiveness and durability of the air coolers. The runner system in these moulds can be either a cold runner or a hot runner, depending on the manufacturer's requirements, further enhancing the versatility of ecson's product offering.

Another aspect where ecson's home appliance moulds stand out is their compatibility with various design software such as UG, ProE, and CAD. This feature allows for seamless integration into the production design workflow, ensuring that the air cooler moulds can be easily and accurately incorporated into the production design process. This compatibility reduces the lead time from design to production, enabling manufacturers to respond swiftly to market trends and consumer demands.

The application scenarios for ecson's air cooler moulds encompass a broad spectrum. In residential settings, the demand for air coolers with aesthetically pleasing designs and efficient cooling capabilities is on the rise, and ecson moulds are instrumental in fulfilling this need. In commercial spaces such as offices, shops, and restaurants, air coolers need to be both effective and blend seamlessly with the interior decor—another scenario where the precision and customization of ecson moulds are crucial. For industrial applications, the robustness and reliability of air coolers are paramount, and the structural integrity imparted by ecson moulds ensures that these devices can withstand the rigors of industrial environments.

In conclusion, the ecson home appliance moulds, including the air cooler moulds, are a vital component in the production of high-quality air cooling systems. The combination of customized design, advanced moulding processes, and software compatibility make these moulds an indispensable tool in the home appliance industry. Whether it's enhancing the comfort of a home, contributing to the ambiance of a commercial space, or ensuring the functionality in an industrial setting, ecson's air cooler moulds are designed to deliver excellence.

Customization:

Brand Name: ecson

Place of Origin: china xiamen

Surface Finish: Polishing

Material: Plastic

Size: Customized

Mould Test: 100% Inspection Before Shipment

Mould Life: 500,000 Shots

Our ecson air cooler mould is expertly crafted with precision and care to meet the highest standards of quality. Originating from Xiamen, China, our mould features a polished surface finish that ensures a high-quality end product. Made from durable plastic material, we offer customized sizes to fit your specific requirements. Each air cooler mould undergoes a rigorous 100% inspection before shipment to guarantee flawless operation. With a mould life of 500,000 shots, you can trust the ecson brand for your air cooler mould needs.

Support and Services:

Our Product Technical Support and Services for the Home Appliance Mould are designed to ensure that you get the most out of your product. With a focus on providing comprehensive assistance, we offer a range of services to support you at every stage of your product's lifecycle. From installation and commissioning to maintenance and troubleshooting, our team of experts is available to provide guidance and technical support.

We understand the importance of keeping your home appliance mould in top condition, and our services are tailored to meet the unique needs of each customer. Whether you are dealing with a complex issue or simply need routine service support, our professional team is committed to delivering solutions that enhance the performance and extend the lifespan of your product.

Additionally, we provide detailed documentation and resources to empower you with the knowledge to operate and maintain your home appliance mould effectively. Our support services are aimed at ensuring maximum uptime, efficiency, and reliability of your product, while also minimizing any potential downtime and disruptions to your operations.

Please note that while we strive to provide exceptional technical support, our services do not include personal contact information. For further assistance or to access our support services, please refer to the specific contact methods provided with your product documentation or on our official website.

Packing and Shipping:

Product Packaging for Home Appliance Mould:

Each Home Appliance Mould is meticulously wrapped in a protective film to prevent scratches and damage during handling. The mould is then cushioned with foam inserts on all sides to ensure it remains secure within its custom-designed corrugated box. The exterior of the box is sealed with heavy-duty packing tape and clearly labeled with handling instructions and product information for easy identification.

Shipping of Home Appliance Mould:

Once the Home Appliance Mould is securely packaged, it is dispatched through our trusted logistics partners. We use palletized shipping for larger moulds to ensure stability and safety during transit. The shipment is trackable, and we provide you with a tracking number so you can monitor your order's progress. Our shipping partners are selected for their reliability and experience in handling industrial goods, ensuring your product arrives on time and in perfect condition.

FAQ:

Q1: What type of home appliance moulds does ecson offer?

A1: Ecson offers a wide range of home appliance moulds, including moulds for plastic components of refrigerators, air conditioners, washing machines, microwaves, and other small appliances. Each mould is designed to meet specific customer requirements and industry standards.

Q2: Can I customize a home appliance mould with ecson?

A2: Yes, ecson specializes in custom mould designs based on your specific needs. You can provide us with your product specifications, and we will work closely with you to create a mould that fits your exact requirements.

Q3: What materials are used in the production of ecson's home appliance moulds?

A3: Ecson uses high-quality steel and aluminum for the construction of their moulds to ensure durability and precision. The choice of material largely depends on the mould design and the intended use of the final product.

Q4: How do I ensure that I am ordering the correct mould for my home appliance?

A4: To ensure you order the correct mould, you should provide all necessary details about your appliance, including dimensions, functionality, and any unique features. Our team at ecson will also assist you in selecting the appropriate mould based on these details.

Q5: How can I place an order for a home appliance mould with ecson, and what is the lead time?

A5: To place an order, you can contact ecson directly through our official website or by reaching out to our sales team. The lead time for a home appliance mould varies depending on the complexity of the design and current production capacity but rest assured that we will provide you with an estimated timeframe during the ordering process.