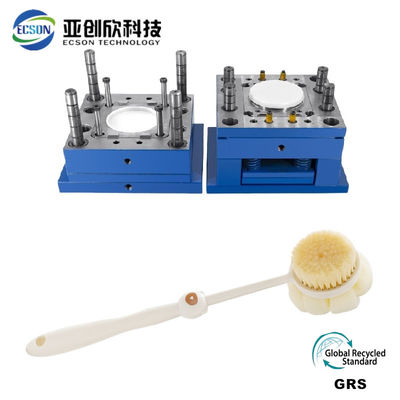

Plastic Long Hand Bath Brush Cooler Mould With Advanced Cooling Design

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Certificate | ISO9001:2015 | Size | Customized |

|---|---|---|---|

| Lead Time | 30-45 Days | Cavity Number | Multi-cavity |

| Mould Test | 100% Inspection Before Shipment | Mould Base | LKM, HASCO, Etc. |

| Surface Finish | Polishing | Runner System | Cold Runner/Hot Runner |

| High Light | Mould Hand Bath Brush,Plastic Mould Hand Bath Brush |

||

Product Description:

The Home Appliance Mould is a high-precision, multi-cavity mould specifically designed for the manufacturing of air coolers. It represents the cutting-edge of moulding technology, offering unparalleled quality and efficiency for your production line. This mould is tailored to meet the rigorous requirements of the air cooler manufacturing process, ensuring that each product produced is of the highest standard. The Home Appliance Mould is fully customizable to fit the unique needs of your products and brand.

Understanding the necessity for precision in the manufacturing process, our Home Appliance Mould is crafted to exacting specifications. Each mould is customized in size to perfectly match the client's requirements, ensuring a flawless fit for the air cooler components being produced. This customization capability is critical in achieving the superior quality and performance that our clients have come to expect from our moulds.

With a focus on productivity and efficiency, the Home Appliance Mould features a multi-cavity design. This allows for the simultaneous production of multiple components, drastically reducing cycle times and increasing output rates. The multi-cavity system is pivotal for manufacturers looking to scale up production without compromising on the quality of their air cooler mould pieces. By utilizing a multi-cavity mould, you can expect a significant boost in your production capabilities.

Quality assurance is at the heart of our manufacturing philosophy. To this end, every Home Appliance Mould undergoes a 100% inspection before shipment. This meticulous testing process ensures that each air cooler mould meets our stringent quality standards. Our commitment to quality inspection means that you can trust our moulds to deliver consistent, high-quality components for your air coolers time and time again. This level of reliability is essential for maintaining the reputation of your products in the market.

The foundation of any mould is its base, and we provide only the best for our clients. The Home Appliance Mould is built on robust and reliable mould bases such as LKM, HASCO, etc. These industry-standard bases are renowned for their durability and compatibility with a wide range of moulding machines. By selecting high-quality mould bases, we ensure that our air cooler moulds are not only effective but also have a long service life, providing you with an excellent return on investment.

We understand that time-to-market is critical in the competitive home appliance industry. That's why we have optimized our processes to offer a lead time of just 30-45 days. This swift turnaround allows you to launch your air cooler products in the market quickly, giving you the advantage of being timely and responsive to market demands. Our efficient lead time, without compromising on quality, sets us apart and makes our Home Appliance Mould an ideal choice for manufacturers looking to maintain a competitive edge.

In conclusion, the Home Appliance Mould is an essential tool for any manufacturer in the air cooler industry. Its customized size, multi-cavity design, rigorous mould testing, high-quality mould base, and quick lead time make it an outstanding investment that can significantly enhance your production capabilities. When you choose our Home Appliance Mould, you choose a product that is synonymous with quality, efficiency, and reliability. Elevate the standard of your air cooler production with our precision-engineered moulds and witness a remarkable transformation in your manufacturing process.

Features:

- Product Name: Home Appliance Mould

- Material: Plastic

- Certificate: ISO9001:2015

- Surface Finish: Polishing

- Runner System: Cold Runner/Hot Runner

- Mould Process: Injection Moulding

- Keywords: air cooler mould, air cooler mould, air cooler mould

Technical Parameters:

| Parameter | Specification |

|---|---|

| Surface Finish | Polishing |

| Cavity Number | Multi-cavity |

| Mould Process | Injection Moulding |

| Lead Time | 30-45 Days |

| Mould Test | 100% Inspection Before Shipment |

| Design Software | UG, ProE, CAD, Etc. |

| Mould Base | LKM, HASCO, Etc. |

| Runner System | Cold Runner/Hot Runner |

| Color | Customized |

| Certificate | ISO9001:2015 |

Applications:

The Ecson brand, hailing from the vibrant city of Xiamen, China, has established itself as a prominent figure in the home appliance mould industry. With a focus on creating high-quality moulds for a variety of household appliances, Ecson has perfected the art of air cooler mould production. The Ecson air cooler moulds are renowned for their precision and durability, attributes that are essential for the mass production of air coolers. These moulds are constructed on robust bases such as LKM, HASCO, etc., ensuring that they are compatible with a multitude of manufacturing systems and are capable of withstanding the rigors of large-scale production.

Ecson air cooler moulds are designed with multi-cavity features, which allows manufacturers to simultaneously produce multiple components, thereby increasing efficiency and reducing production time. This is particularly advantageous during peak seasons when the demand for air coolers surges. The ability to customize the color and size of the moulds allows manufacturers to tailor their production to specific market needs or to adhere to brand standards, making Ecson's moulds a versatile tool in the production arsenal.

The surface finish of these moulds is achieved through meticulous polishing, which not only contributes to the aesthetic appeal of the final product but also ensures smooth demoulding of components, which is crucial to maintain high-quality standards. This attention to detail is indicative of the brand’s commitment to excellence and positions Ecson as a leader in the home appliance mould sector.

Application occasions and scenarios for Ecson's air cooler moulds are diverse. They are indispensable in the manufacturing plants of home appliance companies, where the efficiency and quality of the moulds directly impact production rates and product quality. These air cooler moulds are also crucial during the prototyping phase, as they allow for rapid iteration and refinement of designs, ensuring that the final product meets consumer expectations. Additionally, third-party manufacturing firms that specialize in component production for various brands also rely on these high-grade moulds to deliver consistent and reliable parts.

In summary, Ecson's air cooler moulds are an essential component in the manufacturing process of air coolers, ensuring high-quality, efficiency, and customization for producers worldwide. Their application spans across various scenarios from large scale manufacturing to precise prototyping, reflecting the adaptability and excellence of the Ecson brand.

Customization:

Brand Name: ecson

Place of Origin: china xiamen

Surface Finish: Polishing

Cavity Number: Multi-cavity

Lead Time: 30-45 Days

Mould Process: Injection Moulding

Mould Life: 500,000 Shots

Our ecson home appliance moulds are meticulously designed for air cooler mould applications. With precise polishing as the surface finish and a robust multi-cavity structure, our air cooler moulds are engineered to provide optimal performance. Manufactured in our state-of-the-art facility in Xiamen, China, each air cooler mould undergoes a rigorous injection moulding process to ensure durability and a long mould life of up to 500,000 shots. Expect a reasonable lead time of 30-45 days for your customized air cooler mould needs.

Support and Services:

Our Home Appliance Mould product comes with comprehensive technical support and services designed to provide you with a seamless experience. From installation assistance to maintenance advice, our team of experts is dedicated to ensuring that your mould operates efficiently and effectively. Our services include troubleshooting support to address any operational issues, guidance on optimal usage to extend the lifespan of your mould, and access to detailed product documentation and FAQs. We are committed to delivering quality support to enhance your mould's performance and productivity.

Packing and Shipping:

Our Home Appliance Mould products come in robust, secure packaging to ensure they reach our customers in pristine condition. Each mould is carefully encased in high-density foam that conforms to its shape for added protection against impacts during transit. The foam is then placed inside a sturdy, corrugated cardboard box that provides further cushioning.

Before shipping, all packages are sealed with heavy-duty packing tape and labeled with all the necessary information, including handling instructions and any fragile content warnings. We utilize reliable courier services to ensure timely and safe delivery of your Home Appliance Mould to your doorstep.

Please inspect the package upon arrival for any signs of damage during shipping. In the rare event that you find any damage, contact our customer service immediately to assist you with a replacement or refund. We are committed to providing you with the highest quality products and a smooth, hassle-free delivery experience.

FAQ:

Q1: What types of home appliance moulds does the ecson brand offer?

A1: Ecson offers a wide range of home appliance moulds, including but not limited to moulds for plastic parts of refrigerators, air conditioners, washing machines, and small kitchen appliances. We provide custom mould-making services to fit our clients' specific requirements.

Q2: Can ecson home appliance moulds be customized to my product specifications?

A2: Yes, we specialize in custom mould designs. Our team works closely with clients to ensure the moulds are tailored to their product specifications and manufacturing processes.

Q3: How does the manufacturing process in Xiamen, China, ensure the quality of ecson moulds?

A3: Our manufacturing facility in Xiamen, China, employs advanced technology and strict quality control procedures throughout the production process. This ensures that every ecson mould meets high standards of quality and precision.

Q4: What materials are used to make ecson home appliance moulds?

A4: Ecson uses various high-grade materials to manufacture moulds, including but not limited to steel, aluminum, and corrosion-resistant alloys, to ensure durability and optimal performance.

Q5: How can I order ecson home appliance moulds from Xiamen, China?

A5: You can place an order by contacting our sales team directly through our website or by email. We will guide you through the selection process, customization options, and the ordering procedure.