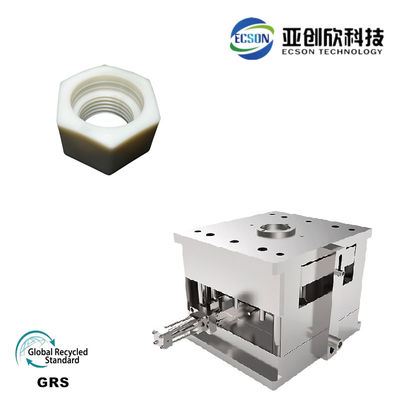

Customized Color Plastic Injection Mold Tooling For Plastic Nuts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface | Smooth | Process | Injection Mold Tooling |

|---|---|---|---|

| Packaging | Standard Export Carton | Hardness | Customized |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory | Shipping | By Sea, Air, Express |

| PaymentTerm | T/T, L/C, Paypal, Western Union | Function | Automobile, Industry, Garden, Construction, Homeappliance Electronics, Houseware |

| Design | Customized 2D/3D Drawing | Lead Time | 4-8 Weeks |

| Application | Manufacturing | Cavity Material | 1.2344 HRC48-52 |

| Mould Life | 500-200 0000shots | Mold Life | 100,000-1,000,000 Shots |

| Design Software | CAD/CAM/CAE | Mold Base Steel | H13,1.2344,4140,1050 |

| Quality | ISO9001 Certification | Mold Size | Small/Medium/Large |

| Mold Cost | $5,000-$100,000 | Mold Material | H13/P20/2738/SKD61/1.2343 |

| Part Surface | Good Polishing /texture/frosted Painting | Runner | Hot Or Cold |

| Part Name | 301567 13in BGM HF Body | ||

| High Light | Plastic Injection Mold Tooling Customized Color,Plastic Nuts Injection Mold Tooling |

||

Customized Color Plastic Injection Mold Tooling For Plastic Nuts

Product Description:

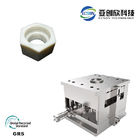

The Plastic Injection Mold Tooling is an advanced manufacturing solution designed to meet the diverse needs of various industries, including Automobile, Industry, Garden, Construction, Home Appliance Electronics, and Houseware. This tooling process is ideal for producing high-quality, precision parts in both small and large volumes. Our service extends to providing OEM/ODM capabilities, ensuring that our clients receive tailor-made products that fit their unique specifications and requirements.

One of the standout features of our Plastic Injection Mold Tooling is the ability to create prototype injection molding. This is a crucial step in the product development process as it allows for the testing and validation of the part design before full-scale production. The prototypes we produce are of the highest quality and are virtually indistinguishable from the final product, which helps in accurately assessing the functionality and fit of the part.

Our injection molding tool is engineered with precision and is capable of producing complex shapes with excellent surface finish. The tooling is created using state-of-the-art technology and is meticulously designed to ensure the highest levels of productivity and efficiency. With our injection molding tool, clients can expect reduced cycle times, enhanced strength and durability of the molded parts, and a significant reduction in the overall production costs.

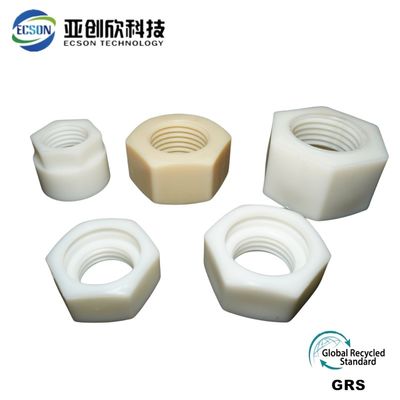

When it comes to customization, we offer the flexibility to work with a variety of sizes and can create a customized size to meet specific customer needs. Our product is available in a transparent color, which is perfect for applications where visibility of the part is essential. Additionally, we offer a range of customized colors according to the Pantone color matching system, providing an array of options to align with your branding or product design requirements.

The shipping of our Plastic Injection Mold Tooling is as versatile as the product itself. We offer various shipping options including By Sea, Air, and Express delivery services. This allows us to accommodate the urgency of your project timelines and ensure that your tooling arrives when you need it, regardless of your global location.

At the core of our service is the commitment to our customers. Our team of experts is dedicated to supporting you through every step of the process, from design to production. We understand the importance of timely delivery and high-quality products, which is why we go above and beyond to exceed your expectations. Our Plastic Injection Mold Tooling service is more than just a product; it's a partnership that drives innovation and success in your business.

In conclusion, our Plastic Injection Mold Tooling is a versatile and efficient solution for businesses looking to produce high-quality parts. With the capability to create both prototype injection molding and final products, customizable size and color options, and a range of shipping methods, we provide a comprehensive service that caters to a wide array of industry needs. Whether you are in the automotive sector, construction, garden products, electronics, or houseware, our tooling service is designed to bring your projects to life with precision and reliability.

Features:

- Product Name: Plastic Injection Mold Tooling

- Color: Transparent, Customized Color According Color Pantone

- Material: Plastic

- Surface: Smooth

- Process: Injection Mold Tooling

- Hardness: Customized

- Keywords: Plastic Injection Molds

- Keywords: Injection Molding Tool

- Keywords: Prototype Injection Molding

Technical Parameters:

| Material | Plastic |

| Packaging | Standard Export Carton |

| Payment Term | T/T, L/C, Paypal, Western Union |

| Hardness | Customized |

| Surface | Smooth |

| Service | OEM/ODM |

| Shipping | By Sea, Air, Express |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

| Process | Injection Mold Tooling |

| Function | Automobile, Industry, Garden, Construction, Home Appliance Electronics, Houseware |

Applications:

The ecson brand specializes in the manufacturing of high-grade Plastic Injection Mold Tooling products that originate from China, renowned for their precision and quality. These tooling solutions are utilized in an array of application occasions and scenarios, serving a variety of industries that demand durable and precise plastic components. Whether you are involved in the automotive, medical, consumer goods, or packaging industries, ecson's custom plastic injection molds offer the reliability and customization necessary to meet the rigorous standards of your specific applications.

One of the primary scenarios for using ecson's injection molding tool is in the mass production of plastic parts. Due to its robustness and smooth surface finish, the tooling is highly sought after for creating complex geometries with tight tolerances. The OEM/ODM service allows for a tailored approach, ensuring that each custom plastic injection mold is engineered to suit the exact size and specifications required by the client. This bespoke service is crucial for manufacturers who need to distinguish their products in competitive markets.

In the realm of consumer electronics, where precision and aesthetic appeal are paramount, ecson's tooling products are indispensable. The smooth surface characteristic of the molds ensures that the final plastic products have an excellent finish, reducing the need for post-processing and thus, accelerating time-to-market for new devices. From smartphone cases to intricate electronic housings, ecson provides the necessary tooling to produce high-quality plastic components.

Moreover, the healthcare industry benefits significantly from the use of ecson's injection molding tool . In an environment where hygiene and precision are non-negotiable, the tooling must produce components that meet strict medical standards. The customizable nature of ecson's molds means that they can be engineered to create plastic parts for medical devices, disposable tools, and even pharmaceutical packaging, all while maintaining the integrity required in medical applications.

The versatility of ecson's Plastic Injection Mold Tooling extends to the automotive industry, where high-performance and durable plastic parts are essential. From interior components to under-the-hood applications, the tooling can withstand the demanding conditions of automotive manufacturing, delivering parts that align with the industry's safety and quality regulations.

When it comes to shipping, ecson offers flexible options including By Sea, Air, and Express, accommodating the tight schedules and logistical preferences of clients globally. This level of service ensures that the tooling products arrive at their destination on time, ready to be integrated into the manufacturing process without delay.

In conclusion, the application occasions and scenarios for ecson's Plastic Injection Mold Tooling are diverse and span across numerous industries. The combination of a smooth surface, customizable size, and material, along with the convenience of OEM/ODM services, makes ecson's custom plastic injection molds the ideal choice for businesses looking to produce high-quality plastic parts efficiently and effectively.

Customization:

Brand Name: ecson

Place of Origin: China

Payment Term: T/T, L/C, Paypal, Western Union

Color: Transparent, Customized Color According to Color Pantone

Item: ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory

Surface: Smooth

Process: Injection Mold Tooling

Our ecson product customization services for Plastic Injection Mold Tooling offer a comprehensive solution for your high-quality manufacturing needs. Whether you require a medical plastic injection mold or any other type of injection molding tool, we provide precision and reliability. The injection moulding process is carried out with meticulous attention to detail, ensuring a smooth surface finish and adherence to your specific color requirements, with an option for transparent or any customized color according to the Color Pantone. Our factory is equipped to handle various materials such as ABS, PP, PC, PE, HDPE, Nylon, and biodegradable plastics, serving a diverse range of industries. Trust ecson for all your plastic injection molding tool requirements in China and benefit from flexible payment options like T/T, L/C, Paypal, and Western Union.

Support and Services:

Our Plastic Injection Mold Tooling product comes with comprehensive technical support and services designed to ensure optimal performance and longevity of your tooling investment. Our support includes professional advice on tool design and engineering, material selection, and process optimization to achieve the highest quality parts with maximum efficiency.

Additionally, we offer preventive maintenance services to help avoid downtime and extend the life of your tooling. Our skilled technicians can provide on-site inspections, cleaning, and repairs as needed. For troubleshooting and technical issues, our dedicated support team is available to assist you with quick and effective solutions.

Moreover, we are committed to continuous improvement and can offer training sessions for your staff to ensure they are up-to-date with the latest injection molding techniques and best practices. This service aims to enhance your team's skills and knowledge to maintain peak operational performance.

Please note that while we strive to provide extensive support, our services do not include the physical production of injection molded parts. We focus solely on ensuring that our tooling products meet the highest standards and that our customers have the necessary support to use them effectively.

Packing and Shipping:

Product Packaging for Plastic Injection Mold Tooling:

All our Plastic Injection Mold Tooling products are packaged with utmost care to ensure they arrive in perfect condition. The tooling is first wrapped in a protective layer of foam or bubble wrap to cushion it against impacts during transport. It is then secured in a sturdy wooden crate, which is custom-built to fit the dimensions of the tooling. The wooden crate provides structural support and protects the tooling from moisture and environmental factors. For added security, the crate is sealed and banded to prevent any movement that could cause damage. Fragile and precision components are given extra attention and may be packaged separately within the crate to ensure they are not compromised.

Shipping for Plastic Injection Mold Tooling:

We take great pride in our shipping process for Plastic Injection Mold Tooling. Once the product is securely packaged, it is labeled with the necessary shipping and handling information, including any fragile or orientation markings. Our logistics team then selects the most reliable shipping service to match the customer's delivery requirements, whether it is by land, sea, or air. We ensure that all packages leave our facility with the appropriate documentation for customs clearance and tracking. The tracking information is shared with the customer so they can monitor their shipment's progress. We also offer expedited shipping options for time-sensitive orders to ensure our customers receive their tooling when they need it.

FAQ:

Q1: What materials can be used with ecson Plastic Injection Mold Tooling?

A1: ecson Plastic Injection Mold Tooling is compatible with a wide range of thermoplastic and thermosetting materials. This includes, but is not limited to, ABS, Polycarbonate, Polypropylene, and Nylon. However, the specific material compatibility may vary depending on the design and specifications of the tooling.

Q2: Can ecson Plastic Injection Mold Tooling be customized for specific product designs?

A2: Yes, ecson specializes in customizing Plastic Injection Mold Tooling to meet the specific needs of your product design. Customers are encouraged to provide detailed requirements and design specifications to ensure the tooling is tailored to their project.

Q3: What is the typical lead time for producing a Plastic Injection Mold with ecson?

A3: The lead time for Plastic Injection Mold Tooling can vary based on the complexity and size of the mold. Typically, the production time ranges from a few weeks to several months. We recommend contacting ecson directly for a more accurate estimate based on your specific tooling requirements.

Q4: How does ecson ensure the quality of their Plastic Injection Mold Tooling?

A4: ecson adheres to strict quality control processes throughout the manufacturing of their Plastic Injection Mold Tooling. This includes the use of precision machining, rigorous testing of the molds, and inspection procedures to ensure that every tool meets high-quality standards.

Q5: Does ecson offer any technical support or assistance in the use of their Plastic Injection Mold Tooling?

A5: Yes, ecson provides technical support and customer service to assist clients with any questions or issues they may encounter while using their Plastic Injection Mold Tooling. Support is available through various channels, including phone, email, or on-site assistance, depending on the nature of the support needed.