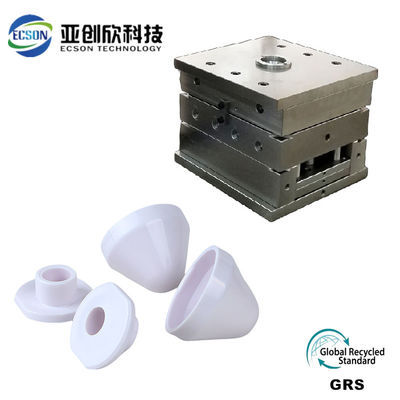

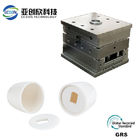

Customized Plastic Single Cavity Injection Mold For Optimal Manufacturing Results

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Process | Injection Mold Tooling | Material | Plastic |

|---|---|---|---|

| Hardness | Customized | Color | Transparent,customized Color According Color Pantone |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory | Surface | Smooth |

| Function | Automobile, Industry, Garden, Construction, Homeappliance Electronics, Houseware | Packaging | Standard Export Carton |

| High Light | Plastic Single Cavity Injection Mold,Customized Single Cavity Injection Mold |

||

Customized Plastic Injection Mold Tooling For Optimal Manufacturing Results

Product Description:

Our Plastic Injection Mold Tooling product is a state-of-the-art solution tailored for manufacturers and businesses that demand precision, reliability, and efficiency in plastic component production. With our cutting-edge technology and expertise, we cater to a wide range of industries, including the medical sector, where the need for high-quality medical plastic injection molds is paramount. Our tooling solutions are designed to meet the rigorous standards required for the production of medical devices and components, ensuring that each product is crafted with the utmost attention to detail and quality.

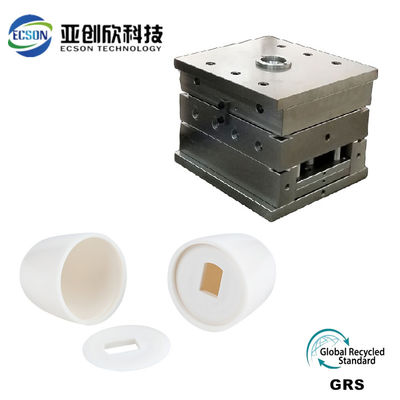

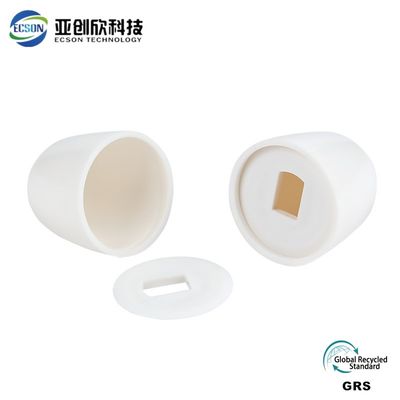

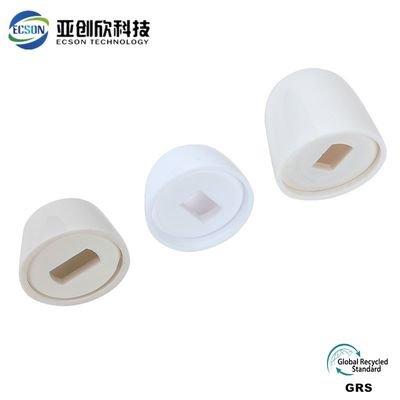

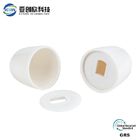

One of the core attributes that set our injection molding tool apart is the surface quality. We guarantee a smooth finish on all our molds, which is critical for the production of high-grade plastic parts. This smooth surface not only contributes to the aesthetic appeal of the final product but also ensures that the parts meet functional specifications without any imperfections that could compromise performance or safety.

In terms of customization, we understand the importance of brand and product differentiation in the market. That's why we offer our molds in transparent and customized colors, with the option to match any hue based on the Color Pantone system. This level of customization allows our clients to maintain brand consistency and meet specific design requirements, adding an extra layer of versatility to our service offering.

Our Plastic Injection Mold Tooling is crafted from premium-grade plastic materials that have been carefully selected for their durability, strength, and suitability for the intended application. We recognize that each project has unique material requirements, especially within the medical sector where the medical plastic injection mold must adhere to strict regulatory standards. Therefore, we work closely with our clients to identify and utilize the most appropriate plastic materials that comply with industry regulations and deliver optimal performance.

Being an OEM/ODM service provider, we take pride in our ability to offer fully customized tooling solutions. Our team of experts collaborates closely with clients to understand their specific needs and develop injection molding tools that are tailored to their unique specifications. We manage the entire process from design to production, ensuring that each mold meets our clients' exact requirements and is ready for seamless integration into their manufacturing processes.

We understand the importance of having flexible payment terms in today's global market, which is why we offer a variety of payment options to accommodate our clients' preferences and financial planning. Our accepted payment terms include T/T, L/C, Paypal, and Western Union, providing our clients with the flexibility to choose the most convenient and secure method for their transactions.

Our commitment to quality extends beyond the manufacturing process. We provide comprehensive support and service to ensure that our clients can maximize the use of their injection molding tool. From troubleshooting and maintenance to optimization and upgrades, our team is dedicated to ensuring that our clients' tooling investments deliver the best possible return.

In conclusion, our Plastic Injection Mold Tooling product embodies a synergy of quality, customization, and client-centric service. It is the perfect choice for businesses looking for a reliable partner to produce medical plastic injection molds and other precise plastic components. By choosing our tooling solutions, clients can expect a smooth surface finish, a wide range of color customization options, top-quality materials, and a partnership that values OEM/ODM services and flexible payment options. Invest in our Plastic Injection Mold Tooling to take your production capabilities to the next level and maintain a competitive edge in the market.

Features:

- Product Name: Plastic Injection Mold Tooling

- Hardness: Customized

- Payment Term: T/T, L/C, Paypal, Western Union

- Surface: Smooth

- Material: Plastic

- Packaging: Standard Export Carton

- Keywords: injection molding tool, plastic injection molds, injection molding tool

Technical Parameters:

| Attribute | Details |

|---|---|

| Payment Term | T/T, L/C, Paypal, Western Union |

| Shipping | By Sea, Air, Express |

| Hardness | Customized |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

| Service | OEM/ODM |

| Packaging | Standard Export Carton |

| Color | Transparent, Customized Color According Color Pantone |

| Process | Injection Mold Tooling |

| Surface | Smooth |

| Material | Plastic |

Applications:

The ecson brand, hailing from China, stands at the forefront of the plastic injection mold tooling industry, offering a diverse range of applications for its high-quality products. The ecson plastic injection molds are engineered for precision and durability, with customized hardness to meet the demanding requirements of various sectors. These molds are carefully packaged in Standard Export Cartons and shipped worldwide through Sea, Air, or Express options, ensuring they arrive at their destinations in optimal condition.

One of the primary applications for ecson's plastic injection mold tooling is in the automotive sector. The molds are utilized to create a myriad of components ranging from interior panels, dashboards, and lighting fixtures to intricate engine parts. This is where the reliability and precision of ecson molds come into play, as the automotive industry demands parts that adhere to strict safety and quality standards.

In the industrial realm, ecson's injection molding tools are indispensable. Whether for creating large-scale machinery components or intricate electronic housings, these tools provide the robustness and exactitude necessary for sustained production under rigorous conditions. For the garden and construction segments, ecson molds facilitate the manufacturing of durable gardening tools, construction equipment, and fixtures, all tailored to withstand the wear and tear of outdoor environments and heavy-duty use.

Home appliances and electronics are other areas where ecson's plastic injection molds are extensively applied. From the sleek exterior of a microwave oven to the complex internal structure of a television set, ecson's molds ensure that each part fits perfectly to the next, ensuring functionality and aesthetic appeal. Moreover, in the houseware category, everything from plastic containers to decorative items can be crafted using ecson's versatile tooling solutions.

One of the most critical uses of ecson's product range is in the medical sector. The medical plastic injection mold is specifically designed to meet the stringent standards of the healthcare industry. These molds are used to produce medical devices, surgical tools, and healthcare products that require absolute precision and cleanliness. Given the life-saving nature of these products, ecson's commitment to quality and excellence is never more evident than in the medical plastic injection mold applications.

The OEM/ODM services provided by ecson allow for a high degree of customization, ensuring that the specific needs of clients are met with utmost precision. Whether it's a bespoke medical plastic injection mold or a standard injection molding tool, ecson's attention to detail and customer-focused service make it an ideal partner for businesses looking to produce high-quality plastic products across a multitude of industries.

Customization:

Brand Name: ecson

Place of Origin: China

Payment Terms: T/T, L/C, Paypal, Western Union

Shipping: By Sea, Air, Express

Material: Plastic

Size: Customized

Function: Suitable for various industries including Automobile, Industry, Garden, Construction, Home appliance, Electronics, and Houseware.

At ecson, we specialize in prototype injection molding , crafting precise injection molding tools to meet your specific design requirements. Our injection molding tool services are tailored to provide custom solutions for a wide range of applications. Ensure your products are built to perfection with ecson's expert Product Customization Services.

Support and Services:

Our Plastic Injection Mold Tooling product is engineered to deliver high-quality performance and reliability. We are committed to providing comprehensive technical support and services to ensure that our customers can leverage the full potential of our tooling solutions. Our professional technical support team is equipped with in-depth knowledge and expertise to address any challenges you may encounter during the operation of your Plastic Injection Mold Tooling.

Our services include troubleshooting guidance, maintenance tips, and process optimization recommendations to enhance the efficiency and lifespan of your tooling. We offer detailed documentation and online resources to assist you with setup, operation, and maintenance procedures. Our aim is to provide prompt and effective support to minimize downtime and maintain your production schedules.

For complex issues that require hands-on assistance, our skilled technicians are available to provide on-site support, ensuring that your tooling is performing optimally. We also offer training sessions for your personnel to ensure they are well-versed in the best practices for operating and maintaining the Plastic Injection Mold Tooling product.

Please note that while we strive to provide comprehensive support, our services are subject to the terms and conditions of your product warranty. We encourage all users to familiarize themselves with the warranty details to understand the full extent of technical support and services available to them.

Rest assured, our commitment to customer satisfaction is our top priority. Our technical support and services are designed to keep your Plastic Injection Mold Tooling in peak condition, ensuring the success of your manufacturing operations.

Packing and Shipping:

Thank you for choosing our high-quality Plastic Injection Mold Tooling. To ensure that your product arrives in pristine condition, we follow strict packaging and shipping protocols. Our tooling is securely encased in a protective layer of foam or bubble wrap to guard against impact during transportation. It is then placed in a sturdy, custom-fitted wooden crate, designed to prevent any movement that could cause damage. The crate is sealed and thoroughly inspected to ensure that it is ready for shipping.

For shipping, we partner with reliable freight carriers who specialize in handling industrial equipment. The tooling is loaded with care onto the transport vehicle and firmly secured. We provide tracking information and a direct contact to our shipping department for any inquiries during transit. Upon arrival, please inspect the packaging for any signs of damage before accepting delivery. If any issues are detected, contact us immediately for assistance.

FAQ:

Q1: What types of plastic can be used with ecson Plastic Injection Mold Tooling?

A1: ecson Plastic Injection Mold Tooling is versatile and can be used with a wide range of thermoplastic materials, including but not limited to ABS, Polycarbonate, Polyethylene, and Polypropylene. The choice of plastic depends on the desired properties of the final product such as strength, flexibility, and heat resistance.

Q2: Can the ecson Plastic Injection Mold Tooling be customized for specific designs?

A2: Yes, the ecson brand specializes in custom mold designs. You can provide your specifications and requirements, and our engineers in China will work with you to create molds tailored to your project's needs.

Q3: What is the typical lead time for producing a mold with ecson Plastic Injection Mold Tooling?

A3: The lead time can vary depending on the complexity and size of the mold, as well as the current production schedule. However, typical lead times range from 4 to 6 weeks after design approval. It's best to contact us for a more accurate estimate based on your specific project.

Q4: How does ecson ensure the quality of their Plastic Injection Mold Tooling?

A4: ecson employs stringent quality control processes at our manufacturing facility in China. This includes precision engineering, rigorous testing of the molds, and quality checks at various stages of production to ensure that the tooling meets the highest standards.

Q5: What industries commonly use ecson Plastic Injection Mold Tooling?

A5: ecson Plastic Injection Mold Tooling is used across various industries including automotive, consumer electronics, medical devices, home appliances, and packaging. Our tooling is adaptable to the needs of diverse manufacturing requirements.