HDPE 3D Printed Plastic Injection Mold Biodegradable Plastic

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| PaymentTerm | T/T, L/C, Paypal, Western Union | Color | Transparent,customized Color According Color Pantone |

|---|---|---|---|

| Size | Customized | Surface | Smooth |

| Process | Injection Mold Tooling | Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

| Hardness | Customized | Shipping | By Sea, Air, Express |

| High Light | HDPE 3D Printed Plastic Injection Mold,Biodegradable 3D Printed Plastic Injection Mold |

||

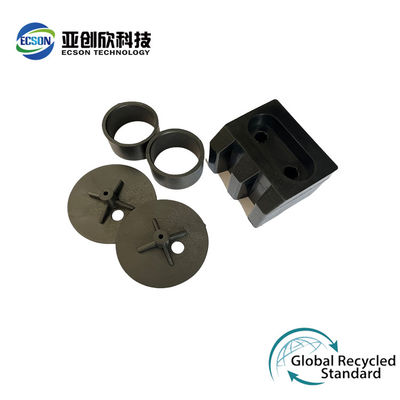

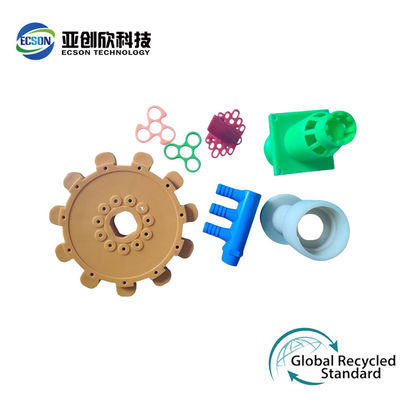

Develop Molds For Various Plastic Accessories Based On Customized Dimensions Of Customer Products

Product Description:

The Plastic Injection Mold Tooling product is a cutting-edge solution for manufacturing high-quality plastic components. This tooling is designed to meet the rigorous demands of the medical industry as well as other sectors that require precision and reliability. The tooling is crafted from durable plastic materials, ensuring longevity and consistent performance throughout its lifecycle. As a testament to its versatility, this product is suitable for both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, catering to a wide range of customer specifications and design requirements.

Our state-of-the-art plastic injection molds are engineered to produce parts with intricate geometries and tight tolerances. The molds are capable of handling various plastic materials, and their robust construction guarantees that they can withstand the high pressures and temperatures involved in the plastic injection molding process. This ensures that the final products are of the highest quality, with excellent surface finish and structural integrity, which is especially crucial in the production of medical plastic injection mold components where precision is paramount.

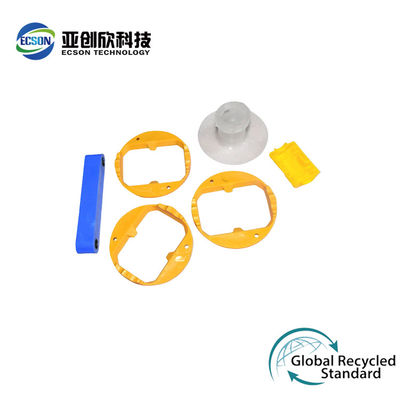

In terms of aesthetics, we offer a range of color options for the plastic components produced using our molds. Our standard color is a clear, transparent finish that showcases the pure quality of the plastic. However, we also provide customized color options according to the Color Pantone system, allowing clients to match the color of their components to their brand identity or design preferences. This level of customization is particularly beneficial for products that require a specific look or need to adhere to branding guidelines.

When it comes to packaging, our Plastic Injection Mold Tooling product is delivered in a Standard Export Carton, ensuring that it reaches our clients in pristine condition. This packaging is meticulously designed to provide ample protection during transit, safeguarding the tooling from potential damage and ensuring that it arrives ready for immediate use. We understand the importance of a hassle-free unboxing experience and have taken every measure to ensure that our packaging meets the highest standards.

Recognizing the diverse needs of our global clientele, we offer a variety of payment terms to facilitate a smooth and convenient transaction process. Clients can choose from T/T (Telegraphic Transfer), L/C (Letter of Credit), Paypal, or Western Union for their payment needs. This flexibility ensures that businesses of all sizes can access our premium plastic injection molds without any financial strain or complexity.

Our commitment to excellence is reflected in every aspect of our Plastic Injection Mold Tooling product. From the premium materials and advanced manufacturing processes to the customizable options and secure packaging, every detail is tailored to provide the utmost value to our clients. We stand behind our product with a dedicated customer service team that is ready to assist with any inquiries or after-sales support. Investing in our plastic injection molds means investing in a product that will deliver consistent results, enhance manufacturing efficiency, and contribute to the success of your business.

Features:

- Product Name: Plastic Injection Mold Tooling

- Item: ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory

- Surface: Smooth

- Packaging: Standard Export Carton

- Shipping: By Sea, Air, Express

- Function: Automobile, Industry, Garden, Construction, Homeappliance, Electronics, Houseware

- Key Feature: High Precision Injection Molding Tool

- Key Feature: Durable Plastic Injection Molds

- Key Feature: Specialized Medical Plastic Injection Mold

Technical Parameters:

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

|---|---|

| Surface | Smooth |

| Material | Plastic |

| Shipping | By Sea, Air, Express |

| Service | OEM/ODM |

| Function | Automobile, Industry, Garden, Construction, Home Appliance, Electronics, Houseware |

| Packaging | Standard Export Carton |

| Hardness | Customized |

| Process | Injection Mold Tooling |

| Size | Customized |

Applications:

The ecson brand, hailing from its place of origin, China , has established itself as a trustworthy provider of high-quality Plastic Injection Mold Tooling products. These versatile tools, crafted from durable plastic materials, are indispensable in the manufacturing and prototyping processes of various industries. The ecson Plastic Injection Mold Tooling is designed to cater to an extensive array of applications, making it an asset for companies looking to streamline their production with precision and efficiency.

In the realm of the automobile industry, ecson 's injection molding tool is pivotal for creating intricate parts that meet the high standards of safety and functionality. The precision of the medical plastic injection mold is equally crucial in the medical sector, where it is employed to manufacture components that are part of life-saving devices, ensuring that they adhere to the stringent regulations of medical-grade products.

The industry and construction sectors benefit from the robustness of ecson 's molds, which are used to produce parts that can withstand the rigors of heavy machinery and infrastructure projects. In the garden equipment market, these tools are instrumental in creating durable and reliable equipment that stands up to the elements and the test of time.

For home appliances and electronics , the ecson Plastic Injection Mold Tooling facilitates the production of components with high precision, ensuring seamless integration and functionality of consumer electronics. In the sphere of houseware , the versatility of the medical plastic injection mold allows for the creation of a myriad of household items that combine aesthetic appeal with practicality.

The ecson Plastic Injection Mold Tooling is globally accessible, with shipping options that include By Sea, Air, and Express to accommodate the various needs of its international clientele. Their commitment to customer satisfaction is further exemplified by their flexible payment terms , which include T/T, L/C, Paypal, and Western Union , offering convenience and security in transactions.

Moreover, ecson provides comprehensive OEM/ODM services , ensuring that every client's specific needs are met with bespoke solutions. Their expertise in the field, coupled with a customer-centric approach, allows for the creation of customized plastic injection molds that cater to the unique requirements of different projects and industries.

Whether it is creating a medical plastic injection mold for the healthcare industry or an injection molding tool for consumer products, ecson delivers quality, efficiency, and reliability in every mold. Their Plastic Injection Mold Tooling stands as a testament to the innovation and craftsmanship that the brand, and its place of origin, China, are known for in the global market.

Customization:

Brand Name: ecson

Place of Origin: China

Material: Plastic

Function: Suitable for various applications including Automobile, Industry, Garden, Construction, Home Appliance Electronics, and Houseware

Payment Term: Flexible payment options including T/T, L/C, Paypal, Western Union

Size: Fully Customized to meet your specific requirements

Item: ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory offering custom plastic injection molds

At ecson, we specialize in the design and manufacturing of high-quality custom plastic injection molds. With precision engineering and state-of-the-art technology, our molds are tailored to meet the unique needs of your Automobile, Industry, Garden, Construction, Home Appliance Electronics, and Houseware products. Rely on ecson for durable and reliable custom plastic injection molds, crafted with expertise in China.

Support and Services:

Our Plastic Injection Mold Tooling comes with comprehensive technical support and services designed to ensure smooth operation and maintenance of your tooling. We are dedicated to providing you with the highest level of customer satisfaction through our expert support services.

Product Installation Guidance: Our team is available to guide you through the proper installation of your Plastic Injection Mold Tooling to ensure optimal performance and longevity.

Technical Consultation: We offer professional consultation to address any technical queries or concerns you may have regarding the operation, maintenance, or customization of your tooling.

On-Demand Troubleshooting: Should you encounter any issues with your Plastic Injection Mold Tooling, our technical support team is ready to assist with troubleshooting to resolve problems swiftly and effectively.

Preventive Maintenance Tips: We provide tips and best practices for preventive maintenance to help you keep your tooling in top condition, reducing downtime and prolonging its service life.

Operational Training: Our experts can provide your staff with training on the correct operation of the tooling, ensuring that your team is well-equipped to use the product efficiently and safely.

Software and Firmware Updates: We keep your tooling up to date with the latest software and firmware updates, ensuring you benefit from the latest features and improvements.

Replacement Parts and Repair Services: In the event that you need replacement parts or repair services, we can provide you with high-quality components and expert service to restore your tooling to its optimal working condition.

Performance Optimization: We can assist you in optimizing the performance of your Plastic Injection Mold Tooling to meet your specific production needs and targets.

Please note that our product technical support and services do not include on-site assistance. However, we are committed to providing remote support and guidance to help you resolve any issues and ensure the best performance of your Plastic Injection Mold Tooling.

Packing and Shipping:

Product Name: Plastic Injection Mold Tooling

Packaging Details:

- Custom protective packaging material to cushion the mold

- Corrosion-resistant wrapping for moisture barrier

- Sturdy wooden crate or pallet for structural support

- Sealed with industrial-grade bands to secure crate integrity

- Labeling with product identification, handling instructions, and cautionary notes

Shipping Details:

- Shipped via freight carrier with tracking and insurance

- Delivery to commercial addresses only

- Liftgate service available upon request for unloading

- Signature required for delivery confirmation

- Expedited shipping options available at additional cost

FAQ:

Q1: What materials are available for ecson Plastic Injection Mold Tooling?

A1: ecson Plastic Injection Mold Tooling can be manufactured using a variety of materials, including but not limited to steel, aluminum, and copper alloys, depending on the specific requirements of the project and the desired properties of the final product.

Q2: Can ecson customize the tooling design to match my product specifications?

A2: Absolutely. ecson specializes in custom tooling designs to meet your exact product specifications. Our engineers will work closely with you to ensure that the tooling is perfectly suited for your application and meets all your requirements.

Q3: What is the lead time for producing a Plastic Injection Mold Tool from ecson?

A3: The lead time for Plastic Injection Mold Tooling can vary depending on the complexity of the tool and current production capacity. Typically, it can range from a few weeks to several months. We recommend contacting us with your specific requirements for a more accurate timeframe.

Q4: How does ecson ensure the quality of its Plastic Injection Mold Tooling?

A4: ecson employs rigorous quality control procedures throughout the manufacturing process. This includes design verification, material inspection, precision machining, and thorough testing of the tooling to ensure it meets all performance and durability standards before shipment.

Q5: What industries does ecson serve with its Plastic Injection Mold Tooling?

A5: ecson's Plastic Injection Mold Tooling is used across various industries including automotive, consumer electronics, medical devices, home appliances, and more. We tailor our services to meet the unique needs of each industry, ensuring optimal results for every project.