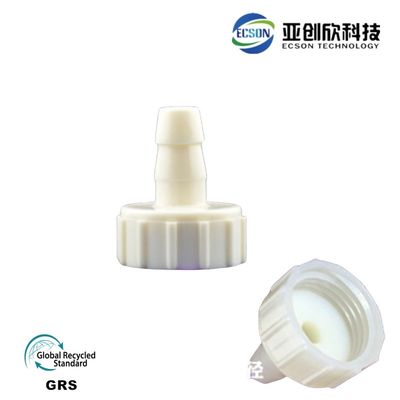

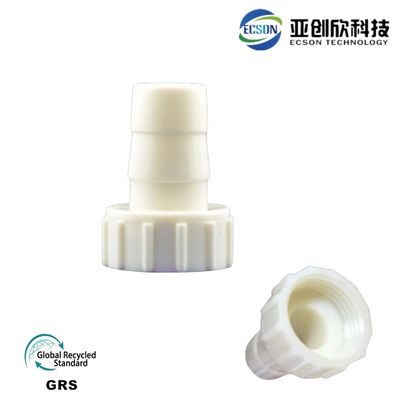

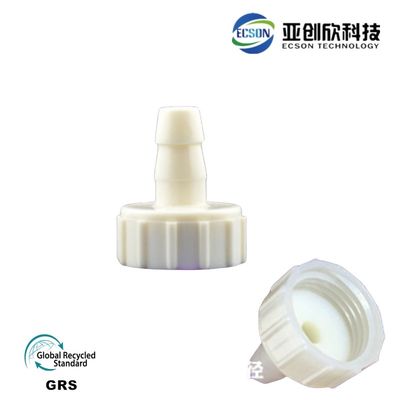

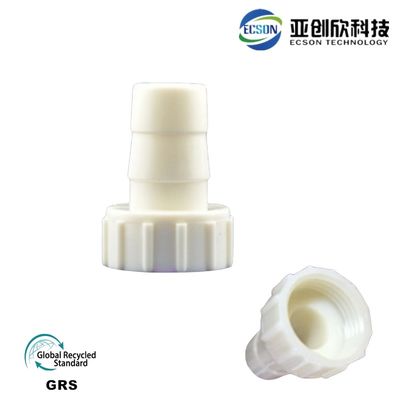

Customized Plastic Injection Mold Tooling PE Plastic Pipe Connectors

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Shipping | By Sea, Air, Express | Function | Automobile, Industry, Garden, Construction, Homeappliance Electronics, Houseware |

|---|---|---|---|

| Process | Injection Mold Tooling | Material | Plastic |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory | Surface | Smooth |

| Hardness | Customized | Packaging | Standard Export Carton |

| High Light | Plastic Injection Mold Tooling Customized,PE Plastic Pipe Connectors |

||

Customized Plastic Injection Mold Tooling For Your Unique Manufacturing Requirements

Product Description:

The Plastic Injection Mold Tooling product is a versatile and essential tool for producing high-quality plastic parts used in a variety of applications. Designed to meet the needs of a broad spectrum of industries, this tooling solution is ideal for creating components for the automobile sector, industrial machinery, garden equipment, construction materials, home appliances, electronic devices, and everyday housewares. The adaptability of plastic injection molds ensures that no matter the complexity or function of the part, it can be accurately and efficiently produced.

One of the key features of our Plastic Injection Mold Tooling is its ability to be customized. Understanding that each application has unique requirements, our molds are designed and manufactured to the exact specifications provided by our clients. This customization extends to the size of the mold, which is tailored to produce the required component size and shape, ensuring a perfect fit and function for the finished product.

Our commitment to quality is evident in the surface finish of the molds. Each mold is crafted to have a smooth surface, which not only contributes to the aesthetics of the molded part but also ensures its functionality by reducing friction and resistance during the molding process. The smooth surface finish is a testament to the precision and care taken during the manufacturing of the mold.

When it comes to materials, we use only premium-grade plastics to ensure the durability and longevity of both the mold and the produced parts. The choice of plastic material is crucial to the success of the product, as it must withstand the high pressures and temperatures involved in the injection molding process while maintaining the integrity of the design.

We are also highly accommodating with payment terms, offering a range of options to suit the financial preferences of our clients. These include T/T (Telegraphic Transfer), L/C (Letter of Credit), Paypal, and Western Union. This flexibility ensures that the transaction process is as smooth and convenient as the surface of our molds.

Our expertise in prototype injection molding allows us to assist clients from the initial stages of product development. Prototype injection molding is an invaluable step in the creation of plastic parts, as it allows for testing and refinement before full-scale production begins. This process helps in identifying potential design flaws and ensuring that the final product will meet the required standards and specifications.

The manufacturing of plastic injection molds is a highly technical process that demands precision engineering and meticulous attention to detail. Our state-of-the-art facilities are equipped with the latest technologies to ensure that each mold is of the highest quality. The production team is comprised of experienced professionals who are dedicated to delivering molds that exceed client expectations.

In conclusion, the Plastic Injection Mold Tooling product is a superior tooling solution that caters to a wide array of industries. It is customizable in size, offers a smooth surface finish, is made from high-quality plastic materials, and comes with flexible payment terms. Whether you are in the business of automobiles, industry, garden, construction, home appliance electronics, or housewares, our plastic injection molds are designed to facilitate the efficient and precise production of your plastic parts. Trust in our expertise in prototype injection molding and our commitment to excellence to bring your products to life with reliability and precision.

Features:

- Product Name: Plastic Injection Mold Tooling

- Function:

- Automobile

- Industry

- Garden

- Construction

- Home Appliance

- Electronics

- Houseware

- Payment Term:

- T/T (Telegraphic Transfer)

- L/C (Letter of Credit)

- Paypal

- Western Union

- Surface: Smooth

- Service: OEM/ODM

- Packaging: Standard Export Carton

- Keywords:

- Prototype Injection Molding

- Plastic Injection Molds

- Custom Plastic Injection Molds

Technical Parameters:

| Parameter | Details |

|---|---|

| Payment Term | T/T, L/C, Paypal, Western Union |

| Size | Customized |

| Process | Injection Mold Tooling |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

| Service | OEM/ODM |

| Color | Transparent, Customized Color According Color Pantone |

| Hardness | Customized |

| Surface | Smooth |

| Material | Plastic |

| Shipping | By Sea, Air, Express |

Applications:

The ecson brand, hailing from China, is renowned for its expertise in the realm of custom plastic injection molds, offering a plethora of application occasions and scenarios. These molds are the backbone of manufacturing for a vast array of plastic products, and the versatility of ecson's Injection Mold Tooling process enables industries to achieve precision and efficiency in their production lines.

One of the primary application scenarios for ecson's plastic injection mold tooling is in the medical industry. The demand for medical plastic injection molds is consistently high due to the need for high-quality, sterile, and precision-engineered components. ecson caters to this need by providing molds that are capable of producing items such as surgical instruments, diagnostic equipment housings, and drug delivery systems. The ability to work with a customized color according to the Pantone color system ensures that medical devices can be manufactured in colors that are suitable for various healthcare settings.

Aside from the medical field, ecson's custom plastic injection molds are widely used in the automotive industry. Customized size and color options allow for the manufacture of intricate components such as dashboard enclosures, lighting systems, and interior fittings, ensuring that the aesthetic and functional requirements of the automotive industry are met with precision.

Consumer products are another area where ecson's plastic injection mold tooling shines. From household items to electronic device casings, the molds can be tailored to suit any size or color specification, allowing OEMs and ODMs to produce products that align with their brand identity and customer expectations. The transparent color option is particularly useful when producing items like water bottles, storage containers, and other products where visibility of contents is a selling point.

ecson facilitates a smooth and secure transaction process by accepting various payment terms such as T/T, L/C, Paypal, and Western Union. This flexibility ensures that businesses around the globe can access ecson's high-quality mold tooling services with ease. The OEM/ODM service provided by ecson further enhances the appeal of their product, as businesses can have their tooling requirements met with a high degree of customization and attention to detail.

In conclusion, ecson's injection mold tooling product is essential in a multitude of industries, where the demand for custom plastic injection molds, and particularly medical plastic injection molds, is ever-growing. The versatility in size and color, coupled with the company's commitment to OEM/ODM services, positions ecson as a go-to source for high-quality, precision mold tooling needs across the globe.

Customization:

Brand Name: ecson

Place of Origin: China

Process: Injection Mold Tooling

Size: Customized according to your specifications

Service: Comprehensive OEM/ODM services to meet all your customization needs

Payment Term: Flexible payment options including T/T, L/C, Paypal, and Western Union

Function: Versatile application for Automobile, Industry, Garden, Construction, Home Appliance, Electronics, and Houseware

At ecson, we specialize in prototype injection molding , crafting precise plastic injection molds for a wide range of industries, including specialized medical plastic injection mold solutions. Our commitment to quality and precision in plastic injection mold tooling ensures that your customized products meet the highest standards.

Support and Services:

Our Plastic Injection Mold Tooling product comes with comprehensive technical support and services to ensure maximum uptime and peak performance. We offer a range of support options designed to meet the needs of our diverse customer base.

Technical Guidance: Our expert team is available to provide guidance on best practices for mold design, material selection, and process optimization to ensure high-quality production output.

Installation Assistance: We provide detailed instructions for the installation of our tooling, and our support team can assist remotely with any challenges that may arise during the installation process.

Maintenance and Repair: Regular maintenance is key to the longevity of your tooling. We offer maintenance tips and schedules, as well as repair services to address wear and tear or any unexpected issues.

Training: To help your staff get the most out of our tooling, we offer training sessions covering operation, maintenance, and safety procedures.

Online Resources: Customers have access to a suite of online resources, including manuals, FAQs, and troubleshooting guides to quickly address common questions and concerns.

Software Updates: We provide software updates for any digital components of the tooling system to enhance functionality and ensure compatibility with the latest technologies.

Continuous Improvement: Our commitment to continuous improvement means we are always working to develop new solutions to enhance the performance and reliability of our tooling products.

For any issues that are not covered by our standard support services, please reach out to our dedicated customer service team for personalized assistance.

Packing and Shipping:

Product Packaging:

All Plastic Injection Mold Tooling products are securely packaged to prevent any damage during transportation. The tooling is first wrapped in a protective film that guards against scratches and corrosion. It is then encased in a cushioning material, such as foam or bubble wrap, to absorb shocks and vibrations. The encased tooling is finally placed within a sturdy wooden crate, which is custom-built to fit the dimensions of the tooling. The crate is sealed and labeled with handling instructions to ensure safe delivery to the destination.

Shipping:

Our Plastic Injection Mold Tooling products are shipped via trusted freight carriers to ensure timely and safe delivery. Once your order is ready, it will be dispatched from our facility within the agreed timeframe. A tracking number will be provided so you can monitor the progress of your shipment. Please note that shipping times may vary depending on the final destination and the current logistics situation. Upon arrival, please inspect the package for any external damage before signing the delivery receipt. In case of any discrepancies, report them immediately to the carrier and our customer service team.

FAQ:

Q1: What materials are available for ecson plastic injection mold tooling?

A1: ecson plastic injection mold tooling can be manufactured using a variety of materials, including but not limited to, steel, aluminum, and various grades of engineering plastics. The choice of material depends on the specific requirements of your project, including the desired durability, production volume, and the type of plastic being molded.

Q2: Can ecson provide custom mold designs for my specific product needs?

A2: Yes, ecson specializes in custom mold designs. Our experienced design team in China can work with you to create a mold that meets your exact specifications. We use the latest CAD/CAM software to ensure precision and quality in our mold designs.

Q3: What is the lead time for a custom plastic injection mold from ecson?

A3: The lead time for a custom plastic injection mold can vary depending on the complexity of the mold and the current production schedule. Generally, the process can take anywhere from a few weeks to several months. We recommend contacting us with your specific requirements for a more accurate timeline.

Q4: Does ecson offer any prototyping services before full-scale production?

A4: Yes, ecson offers prototyping services. We can create a prototype mold for initial testing and evaluation before proceeding to full-scale production. This ensures that any design adjustments can be made early in the process, saving time and cost in the long run.

Q5: How does ecson ensure the quality of their plastic injection molds?

A5: Quality is a top priority at ecson. We conduct rigorous inspections throughout the manufacturing process, from the initial design to the final production of the mold. Our molds are produced in China under strict quality control measures, using high-precision machinery and adhering to international quality standards.