Single Cavity Plastic Injection Mold Assembly With Hot Cold Runner System

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mould Cavity | Single Cavity, Multi-cavity | Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

|---|---|---|---|

| Runner System | Hot Runner And Cold Runner | Product Name | Plastic Injection Molding Assembly |

| Color | Black | Mould Life | 100K-1000K Shots |

| High Light | Single Cavity Injection Mold Assembly,Cold Runner Plastic Injection Mold Assembly |

||

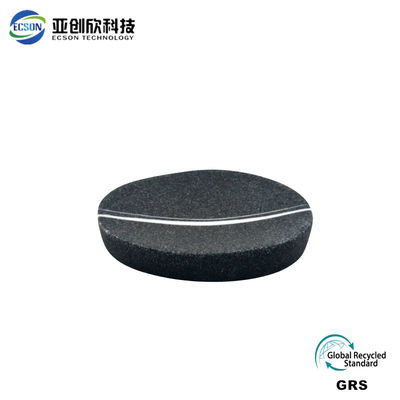

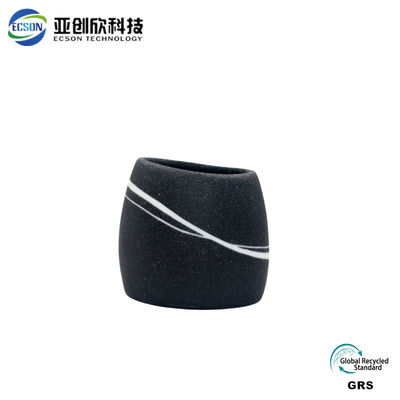

Single Cavity Mould Cavity Injection Mold Assembly With Hot And Cold Runner System

Product Description:

The Plastic Injection Molding Assembly represents a pinnacle of modern manufacturing precision, integrating advanced technologies and engineering expertise to deliver high-quality plastic components for a wide array of industries. This product is at the forefront of injection mold assembly, offering a versatile solution that caters to the complex and diverse needs of clients.

Our Plastic Injection Molding Assembly is constructed to endure, with a mold life ranging from 100K to 1000K shots. This longevity ensures that customers are investing in a product that will sustain high productivity over an extended period. Consistent quality is maintained throughout the mold's life, providing peace of mind and significant value for any project.

To facilitate a seamless integration into existing production lines, we provide comprehensive product drawings. Clients can access detailed 2D and 3D drawings, closely examined product samples, or multi-angle pictures that display the dimensions with precision. These resources are invaluable in confirming that the injection mold assembly meets the exact specifications required for the intended application.

Understanding the critical role of the runner system in the molding process, our Plastic Injection Molding Assembly can be configured with either a hot runner or a cold runner system. The hot runner system is designed to reduce waste and improve cycle times by keeping the plastic melted throughout the process, which is ideal for larger volumes and complex parts. Conversely, the cold runner system is a cost-effective option that allows for easier color changes and is suitable for simpler designs or short-run productions.

At the heart of the Plastic Injection Molding Assembly is the versatility offered by the mold cavity design. Clients can opt for a single cavity mold for focused, high-precision production or a multi-cavity mold for increased throughput and efficiency. This level of customization is essential in injection molding and assembly processes, as it allows for the optimization of production according to the specific needs of each project.

The robustness of the Plastic Injection Molding Assembly is not just in its physical design but also in its adaptability to various applications. Whether for automotive components, medical devices, consumer goods, or electronic housings, our injection molding and assembly services are equipped to handle the challenges and intricacies of producing complex plastic parts.

Equipped with cutting-edge technology, our Plastic Injection Molding Assembly is engineered to deliver precision, efficiency, and reliability. The meticulous design and manufacturing process ensure that every aspect of the injection mold assembly is optimized for performance. From the selection of materials to the application of rigorous quality control measures, every step is taken to ensure that the final product exceeds industry standards and client expectations.

In summary, the Plastic Injection Molding Assembly is a testament to the advancements in injection molding and assembly. With its long mold life, customizable runner systems, and flexible cavity configurations, it stands as an essential tool for businesses looking to streamline their production processes and achieve superior product outcomes. By choosing our Plastic Injection Molding Assembly, clients are assured of a product that embodies precision, durability, and adaptability.

Features:

- Product Name: Plastic Injection Molding Assembly

- Runner System: Hot Runner and Cold Runner

- Color Options: White, Black, Gray, Green, Blue

- Mould Cavity: Single Cavity, Multi-cavity

- Product Drawings: Includes 2D Drawings, 3D Drawings, Product Samples, or The Size Of The Multi-angle Pictures

Technical Parameters:

| Parameter | Details |

|---|---|

| Product Name | Plastic Injection Molding Assembly |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Color | White, Black, Gray, Green, Blue |

| Runner System | Hot Runner And Cold Runner |

| Mould Life | 100K-1000K Shots |

| Mould Cavity | Single Cavity, Multi-cavity |

Applications:

The ecson Plastic Injection Molding Assembly hailing from Xiamen, China , is a sophisticated and versatile solution for various product manufacturing industries. This innovative assembly system is suitable for a vast array of applications, owing to its reliable mold life that ranges between 100K to 1000K shots. With the flexibility of Single Cavity and Multi-cavity options, the ecson assembly adapts to the specific production requirements, ensuring efficiency and precision.

One of the primary application occasions for the ecson injection mold assembly is within the automotive industry. Here, the high-volume production of complex, durable parts such as dashboard panels, lighting components, and interior casings is essential. The ecson system, with its robust mould life and adaptable cavities , can handle the demands of this sector, providing parts that meet strict industry standards.

In the realm of consumer electronics, the ecson injection molding assembly is equally applicable. Manufacturers of smartphones, tablets, and other personal devices require precise and reliable components such as plastic housings, buttons, and camera modules. The ecson's Hot Runner and Cold Runner systems ensure that every part is molded with accuracy, maintaining the aesthetic and functional standards expected by consumers.

Medical device manufacturers also benefit from the high-quality standards of the ecson injection molding assembly. The production of sterile, biocompatible plastic parts such as syringe components, surgical instruments, and diagnostic device housings require the utmost precision and reliability. The ecson assembly's capacity for detailed 2D Drawings, 3D Drawings, Product Samples, or the Size of Multi-angle Pictures ensures that each product meets the critical specifications for medical use.

Furthermore, the versatility of the ecson assembly makes it suitable for creating packaging solutions for various industries. Whether it's food and beverage, pharmaceuticals, or consumer goods, the ability to produce multi-cavity molds allows for high efficiency in producing caps, containers, and intricate packaging components. The ecson injection molding assembly's advanced runner systems contribute to a streamlined and cost-effective manufacturing process.

In conclusion, the ecson Plastic Injection Molding Assembly is a formidable player in the injection molding industry. Its application scenarios are diverse, ranging from automotive to consumer electronics, medical devices, and packaging. The combination of its long mold life, flexible cavity options, and precise runner systems, along with comprehensive product drawing support, makes it a preferred choice for quality-driven manufacturers around the globe.

Customization:

Enhance your manufacturing capabilities with ecson 's premium Plastic Injection Molding Assembly services. Crafted with precision and care in the bustling industrial city of China Xiamen , our injection molding assembly solutions are engineered to meet the diverse needs of modern production lines.

Our state-of-the-art Runner System employs both Hot Runner and Cold Runner technologies to ensure efficient and high-quality plastic injection processes. Whether you have 2D Drawings, 3D Drawings , precise Product Samples , or require assistance with determining the size from Multi-angle Pictures , we tailor our services to fit your specific design requirements.

The injection molding assembly services we offer can accommodate a variety of production volumes with our Mould Cavity options, featuring both Single Cavity and Multi-cavity systems. This flexibility ensures that whether you are running a small batch or large scale production, our systems are designed to adapt seamlessly.

At ecson, we understand the importance of longevity and cost-efficiency in manufacturing. Our Plastic Injection Molding Assembly products are built to last, with a Mould Life ranging from 100K to 1000K Shots , providing you with a reliable and durable manufacturing solution. Trust in the expertise of ecson for all your injection molding assembly needs.

Support and Services:

Our Plastic Injection Molding Assembly is designed to deliver high-quality performance and reliability for your production needs. To ensure that you can leverage the full potential of our product, we offer comprehensive technical support and services.

If you encounter any issues or have questions regarding the operation, maintenance, or optimization of your Plastic Injection Molding Assembly, our team of expert technicians is ready to provide you with the assistance you need. Our support services include troubleshooting, process optimization advice, and guidance on best practices to enhance product efficiency and longevity.

We also offer regular service check-ups and maintenance programs to help keep your Plastic Injection Molding Assembly in optimal condition, thus preventing downtime and ensuring continuous operation. Our proactive services are designed to identify and address potential issues before they become problems, saving you time and resources in the long run.

Additionally, our support extends to providing access to a wide range of replacement parts and upgrades that are specifically designed to work seamlessly with your Plastic Injection Molding Assembly. This ensures that any parts you may need are of the highest quality and compatibility.

For more detailed guidance, refer to our user manual which contains comprehensive information on installation, operation, and maintenance. We are committed to your satisfaction and aim to provide the support you need to achieve success with our products.

Packing and Shipping:

Product Packaging for Plastic Injection Molding Assembly:

Each unit is individually encased in a protective, polyethylene foam sleeve to prevent scratches during handling. The encased units are then placed into custom-designed, corrugated boxes that secure the assemblies from movement during transportation. Each box is sealed with industrial-grade packing tape to ensure it remains closed and intact throughout the shipping process.

Shipping Information for Plastic Injection Molding Assembly:

Our Plastic Injection Molding Assemblies are shipped via trusted freight carriers to ensure timely and safe delivery. Each shipment is accompanied by a detailed packing list and tracking information is provided upon dispatch. We offer standard and expedited shipping options to accommodate your scheduling needs. For large orders or special shipping requirements, please contact our customer service team to arrange customized logistics solutions.

FAQ:

Q: What is the ecson Plastic Injection Molding Assembly?

A: The ecson Plastic Injection Molding Assembly is a manufacturing process used to produce complex plastic parts and components. It involves injecting molten plastic material into a mold to create parts with precise dimensions and shapes.

Q: What materials are used in the ecson Plastic Injection Molding Assembly?

A: ecson utilizes a variety of thermoplastic materials in their injection molding process, including but not limited to ABS, Polycarbonate, Polypropylene, and Nylon, depending on the requirements of the product and its application.

Q: Can ecson customize the design of the Plastic Injection Molding Assembly for my product?

A: Yes, ecson offers custom design services for their Plastic Injection Molding Assembly. You can work with their design team to create a mold that fits your specific needs and product specifications.

Q: How does the quality control process work for the ecson Plastic Injection Molding Assembly?

A: ecson has a strict quality control process that includes multiple quality checks throughout the production cycle. This ensures that all molded parts meet the required specifications and quality standards before they are shipped to customers.

Q: How do I place an order for the ecson Plastic Injection Molding Assembly from Xiamen, China?

A: You can place an order for the ecson Plastic Injection Molding Assembly by contacting their sales team directly. They will guide you through the process, from design and prototyping to final production and shipping.