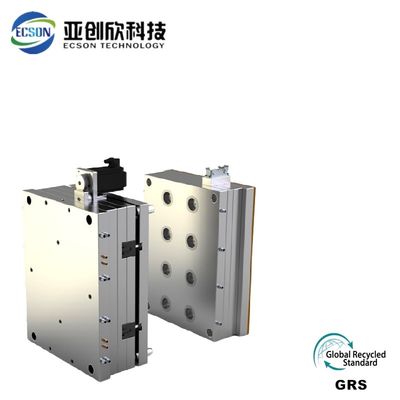

Customizable Plastic Injection Molding Assembly 2D Drawings For Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Runner System | Hot Runner And Cold Runner | Product Name | Plastic Injection Molding Assembly |

|---|---|---|---|

| Mould Life | 100K-1000K Shots | Mould Cavity | Single Cavity, Multi-cavity |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures | Size | Customizable |

| Tolerance | Tight | Application | Various Industries |

| Weight | Customizable | Lead Time | Short |

| Production Method | Injection Molding | Production Volume | Large Scale |

| Material | Plastic | Surface Finish | Smooth |

| Cost | Competitive | Color | Customizable |

| Durability | High | Precision | High |

| Assembly Type | Fully Assembled | ||

| High Light | Customizable Plastic Injection Molding Assembly,2D Drawings Plastic Injection Molding Assembly |

||

Product Description:

The Plastic Injection Molding Assembly represents a significant advancement in the field of manufacturing, combining the precision of modern injection molding techniques with the efficiency of streamlined assembly processes. This product is designed to cater to a variety of industries, from automotive to consumer electronics, medical devices, and beyond, offering a customizable solution for mass production of plastic parts with complex geometries and tight tolerances.

Available in a versatile palette of colors including White, Black, Gray, Green, and Blue , the Plastic Injection Molding Assembly can be tailored to meet the aesthetic requirements of any product design. The coloration process is meticulously managed to ensure consistency and durability, so that each part maintains its hue throughout its lifespan, despite exposure to environmental factors and everyday wear and tear.

One of the critical aspects of the Plastic Injection Molding Assembly is its capability to accommodate both Single Cavity and Multi-cavity moulds. Single cavity molds are ideal for lower volume production or for components that require larger dimensions, while multi-cavity molds are the go-to for high volume production, allowing multiple parts to be produced simultaneously. This versatility ensures that the production can be scaled according to the needs of the project without compromising on the quality or efficiency of the output.

Durability and longevity are key considerations in the manufacturing of injection molds, and the Plastic Injection Molding Assembly boasts an impressive Mould Life of 100K-1000K Shots . This range signifies the number of parts that can be created before the mold begins to show signs of wear, indicating a significant return on investment for mass production scenarios. The long lifespan of the molds not only drives down the cost per unit but also supports a more sustainable manufacturing approach by reducing the need for frequent mold replacements.

A crucial element in the injection molding process is the Runner System , and the Plastic Injection Molding Assembly integrates both Hot Runner and Cold Runner systems. Hot runners are advanced systems that maintain the molten state of the plastic as it moves from the machine's nozzle into the mold cavities, thus minimizing waste and facilitating faster cycle times. Cold runners, on the other hand, allow for simpler mold designs and can reduce initial tooling costs. The choice between a hot or cold runner system can be tailored based on the specific requirements of the project, balancing cost, and production efficiency.

The process of injection molding and assembly is a multi-step one that involves injecting molten plastic into a mold where it solidifies and is then ejected to be assembled with other components. This assembly phase is often automated to ensure precision and consistency. The integration of injection molding and assembly in a single workflow streamlines the production process, resulting in shorter lead times and reduced labor costs. It also enhances the overall quality of the final product, as the transition from molding to assembly occurs within a controlled environment, mitigating the risk of part contamination or damage.

The technological sophistication of injection molding and assembly has been a game-changer in the production of complex plastic parts. With the capability to produce intricate designs with excellent surface finishes, the Plastic Injection Molding Assembly system has become indispensable in industries where precision and reliability are paramount. Moreover, the system's adaptability allows for the incorporation of various plastic materials, including thermoplastics, thermosetting plastics, and elastomers, further broadening its application scope.

In conclusion, the Plastic Injection Molding Assembly stands as a testament to the evolution of the manufacturing process. Its combination of color variety, mold cavity options, extended mold life, and choice of runner systems, all integrated into a seamless injection molding and assembly process, makes it an ideal solution for creating high-quality plastic components at scale. It empowers manufacturers to achieve efficiency, sustainability, and cost-effectiveness, ultimately contributing to a more dynamic and innovative production landscape.

Features:

- Product Name: Plastic Injection Molding Assembly

- Product Drawings:

- 2D Drawings

- 3D Drawings

- Product Samples

- Size Of The Multi-angle Pictures

- Runner System:

- Hot Runner

- Cold Runner

- Mould Cavity:

- Single Cavity

- Multi-cavity

- Color:

- White

- Black

- Gray

- Green

- Blue

Technical Parameters:

| Attribute | Details |

|---|---|

| Mould Cavity | Single Cavity, Multi-cavity |

| Runner System | Hot Runner And Cold Runner |

| Product Name | Plastic Injection Molding Assembly |

| Mould Life | 100K-1000K Shots |

| Color | White, Black, Gray, Green, Blue |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

Applications:

The Plastic Injection Molding Assembly from ecson is a versatile and essential component in many industrial and commercial applications. Manufactured with precision in China Xiamen , this product stands out for its reliability and customizability. The assembly process is supported by comprehensive 2D Drawings, 3D Drawings, Product Samples, or the Size of the Multi-angle Pictures , ensuring a seamless integration into the client's requirements.

The use of advanced runner systems , including both Hot Runner and Cold Runner technologies, allows for efficient and cost-effective production. The ecson Plastic Injection Molding Assembly can be implemented in a diverse range of scenarios. Whether it's for automotive components, consumer electronics, medical devices, or household appliances, the adaptability of the injection molding and assembly process makes it an ideal choice.

Available in a spectrum of colors such as White, Black, Gray, Green, and Blue , this product can be tailored to fit the aesthetic and design specifications of almost any product. The high-quality materials used in the injection mold assembly ensure that the colors remain vivid and consistent throughout the product's lifespan, which ranges from 100K to 1000K shots depending on the mold's life.

Applications of the Plastic Injection Molding Assembly are vast, spanning across various occasions such as mass production runs, custom product designs, or rapid prototyping. The injection mold assembly process is critical in producing parts with complex geometries and tight tolerances, and ecson ensures the highest standards are met. Industries such as aerospace, defense, and packaging regularly employ this technology for its precision and durability.

In summary, the ecson Plastic Injection Molding Assembly is a highly adaptable product that excels in multiple scenarios. Its application in creating robust, precise, and aesthetically pleasing parts makes it a preferred choice for businesses looking to maintain a competitive edge in their respective markets. The combination of Chinese manufacturing excellence and advanced injection molding and assembly techniques results in a product that is not only efficient in production but also exceptional in performance.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Product Name: Plastic Injection Molding Assembly

Mould Cavity: Our services include both Single Cavity and Multi-cavity options to suit your injection mold assembly requirements.

Color: Available in a variety of colors including White, Black, Gray, Green, Blue to match your injection mold assembly specifications.

Mould Life: Durable mould life ranging from 100K to 1000K Shots, ensuring long-term reliability for your injection mold assembly needs.

Runner System: Equipped with both Hot Runner and Cold Runner systems to optimize the efficiency of your injection mold assembly process.

Support and Services:

Our Plastic Injection Molding Assembly product comes with comprehensive technical support and services designed to ensure your manufacturing processes run smoothly. Our team of experts is dedicated to providing you with the assistance you need to maximize the efficiency and productivity of your equipment.

Support services include but are not limited to:

- Onboarding and Training: Detailed instructions and training sessions for your staff to familiarize them with the operation and maintenance of the assembly system.

- Troubleshooting: Assistance in diagnosing and resolving any operational issues that may arise, ensuring minimal downtime for your production line.

- Maintenance Guidelines: Recommendations on routine maintenance practices to keep your equipment in optimal condition and prevent wear and tear.

- Upgrade Advice: Information on the latest upgrades and enhancements available for your assembly system to keep it up-to-date with current technologies.

- Replacement Parts: Guidance on selecting and obtaining the appropriate replacement parts to maintain the integrity and performance of your system.

Please note that our technical support and services are available during regular business hours and may vary depending on your location and the specific terms of your service agreement. We are committed to providing you with the highest level of service to ensure your Plastic Injection Molding Assembly product operates at its best.

Packing and Shipping:

Our Plastic Injection Molding Assembly products are packaged with utmost care to ensure they arrive at their destination in the same impeccable condition they left our facility. Each assembly is wrapped in a protective layer of bubble wrap to cushion against impacts during transit. The wrapped products are then placed in a sturdy, corrugated cardboard box, specifically sized to minimize movement and prevent damage.

Inside the box, additional packing materials are used to fill any voids, providing extra stability. The box is then sealed with heavy-duty packing tape and labeled with the appropriate shipping information and handling instructions to guarantee the package is treated correctly throughout its journey.

Prior to shipping, each package undergoes a final inspection to confirm that it meets our high standards for quality and safety. We partner with reliable shipping carriers to ensure timely delivery, and all items are shipped with a tracking number so that you can monitor the progress of your shipment until it reaches its destination.

FAQ:

Q1: What types of plastic materials can be used with ecson's Plastic Injection Molding Assembly?

A1: ecson's Plastic Injection Molding Assembly is compatible with a wide range of plastic materials, including but not limited to ABS, Polycarbonate, Polypropylene, Polyethylene, and thermoplastic elastomers. The specific material to be used can be selected based on the requirements of the product being manufactured.

Q2: Can ecson's Plastic Injection Molding Assembly be used for high-volume production?

A2: Yes, ecson's Plastic Injection Molding Assembly is designed for high-volume production, providing efficient and consistent output for large runs of plastic parts. The machinery is built to maintain quality and precision even during extensive operation periods.

Q3: Are there any size limitations for products made with ecson's Plastic Injection Molding Assembly?

A3: The size of products that can be manufactured using ecson's Plastic Injection Molding Assembly largely depends on the specific model of the machine and the capacity of the mold being used. We offer a variety of machine sizes to accommodate different product dimensions. Please contact us with your product specifications for more detailed information.

Q4: What industries commonly use ecson's Plastic Injection Molding Assembly?

A4: ecson's Plastic Injection Molding Assembly is versatile and can be used across various industries, including automotive, consumer electronics, medical devices, packaging, and household goods, among others. Its adaptability to different materials and precision makes it suitable for a wide range of applications.

Q5: How can I order a custom mold for use with ecson's Plastic Injection Molding Assembly?

A5: To order a custom mold for use with our Plastic Injection Molding Assembly, please reach out to our sales team with your design specifications and requirements. Our team will guide you through the design process, mold fabrication, and will ensure that the custom mold meets your exact needs for the production process.