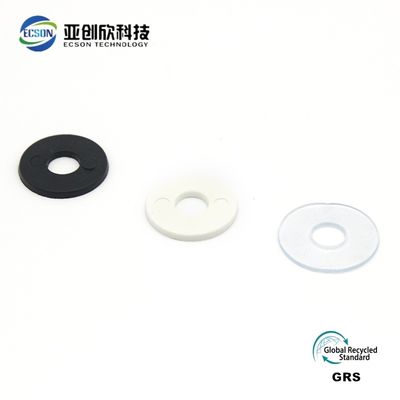

Polishing Surface Finish CNC Machining Plastic Parts for Black connecting gasket

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | CNC Machining Plastic Parts | Shape | Customized |

|---|---|---|---|

| Process | CNC Machining | Shipping Method | By Air, By Sea, By Express |

| Color | White,black | Material | Plastic |

| Application | Industrial | Surface Finish | Polishing |

Product Description:

Our CNC Machining Plastic Parts product stands as a pinnacle of modern industrial manufacturing, offering a robust solution for a diverse array of applications. With precision engineering and meticulous attention to detail, this product caters to the demands of industries that require high-quality, custom-made plastic components. Designed to accommodate the versatile needs of our clients, these CNC plastic parts are crafted using advanced Computer Numerical Control (CNC) technology, ensuring that each piece meets the highest standards of accuracy and excellence.

The application of these machined plastic components extends across various sectors, including aerospace, medical, automotive, and consumer electronics. Their adaptability makes them ideal for prototypes, custom fittings, and intricate assemblies, where precision and reliability are paramount. The versatility of our CNC plastic parts is further enhanced by our ability to work with a wide array of plastic materials, each selected for its unique properties and suitability for specific industrial applications.

Each CNC Machining Plastic Parts project begins with a detailed blueprint. Our skilled technicians are proficient in interpreting a range of drawing formats such as CAD, PDF, IGS, STP, and X_T. This flexibility allows us to seamlessly integrate into our clients' workflows, ensuring that the final product is a true representation of the intended design. With such a comprehensive approach to design interpretation, we guarantee that every machined plastic component is produced with utmost fidelity to the original concept.

Understanding the time-sensitive nature of industrial projects, we are committed to maintaining an efficient production pipeline. Our standard lead time for the delivery of CNC plastic parts is between 7 to 15 days, balancing rapid turnaround with the meticulous care required for precision machining. This swift lead time ensures that our clients' projects stay on schedule, minimizing downtime and accelerating the path to market for new products and innovations.

Once the manufacturing process is complete, the finished CNC plastic parts are prepared for shipping. We offer a variety of shipping methods to suit the needs and preferences of our clients, including air, sea, and express delivery options. By providing multiple shipping methods, we ensure that our clients receive their machined plastic components promptly and securely, regardless of their geographic location.

One of the critical aspects of our CNC Machining Plastic Parts is the unparalleled accuracy we guarantee. Our state-of-the-art CNC machines operate with a standard tolerance of ±0.01mm. This level of precision underscores our commitment to quality and is a testament to the skill of our operators and the capability of our technology. Such tight tolerances are essential for applications that require components to fit and function seamlessly within complex assemblies, where even the slightest deviation can compromise the entire system.

In conclusion, our CNC Machining Plastic Parts product offers an exceptional choice for industries in need of high-precision, custom cnc plastic parts. By combining advanced technology, flexible design interpretation, efficient production, and versatile shipping options, we provide a comprehensive solution that meets the stringent requirements of modern industrial operations. Each machined plastic component is a product of our dedication to excellence, from the initial design stages to the final delivery, ensuring that our clients receive nothing but the best in CNC machining services.

Features:

- Product Name: CNC Machining Plastic Parts

- Size: Customized

- Color: Customized

- Drawing Format: CAD/PDF/IGS/STP/X_T

- Packing: Carton Box

- Keywords: machined plastic parts, cnc plastic parts, precision cnc plastic components

Technical Parameters:

| Attribute | Details |

|---|---|

| Color | Customized |

| Surface Finish | Polishing |

| Tolerance | ±0.01mm |

| Shape | Customized |

| Packing | Carton Box |

| Lead Time | 7-15 Days |

| Process | CNC Machining |

| Size | Customized |

| Shipping Method | By Air, By Sea, By Express |

| Drawing Format | CAD/PDF/IGS/STP/X_T |

Applications:

The ecson CNC Machining Plastic Parts are precision-engineered components that are vital in a multitude of applications across various industries. Originating from Xiamen, China, these parts are the epitome of custom manufacturing, designed to meet specific client requirements. The process of CNC machining ensures high accuracy and consistency, making these parts essential for applications where precision is critical.

One of the primary application occasions for these custom machined plastic parts is in the medical industry. Here, they are used in the creation of specialized medical devices and equipment. Due to the stringent standards required in medical technology, the parts produced need to adhere to exact specifications, which is guaranteed by the CNC machining process and the ability to work with a range of drawings formats such as CAD, PDF, IGS, STP, and X_T.

In the field of robotics and automation, machined plastic components from ecson are indispensable. As robots and automated machines demand parts that are both lightweight and durable, the use of CNC machined plastic parts is a perfect match. These parts often form the structural framework of robots or are used in intricate mechanisms within automated systems.

Aerospace is another sector where the attributes of ecson machined plastic parts are highly valued. Components for aerospace applications must withstand extreme conditions while maintaining precise tolerances. ecson's ability to create custom shapes using a diverse range of plastics ensures that aerospace engineers can rely on these components for both prototyping and end-use applications.

Furthermore, in the automotive industry, the shift towards more innovative and efficient vehicles has seen an increase in the use of machined plastic parts. From the internal mechanisms in engines to the aesthetically pleasing finishes in interiors, these parts are integral to modern vehicle design. The CNC machining process offers the versatility and precision that automotive designers require for both form and function.

Lastly, consumer electronics is an industry in which the ecson CNC machined plastic parts are extensively used. The compact and intricate components inside gadgets such as smartphones, laptops, and cameras are often produced using the CNC machining process. The customizability of these components ensures that they fit perfectly within the sleek designs of modern electronics, while the plastic material offers excellent insulation properties and durability.

In summary, the ecson CNC Machining Plastic Parts are a cornerstone in industries that demand precision, customization, and quality. Whether it's for medical devices, robotics, aerospace, automotive, or consumer electronics, these parts are crafted to perform exceptionally in a variety of scenarios and applications.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Surface Finish: Polishing

Process: CNC Machining

Shipping Method: By Air, By Sea, By Express

Size: Customized

Packing: Carton Box

At ecson, we specialize in the production of high-quality cnc plastic parts tailored to meet your specific requirements. Our custom CNC plastic parts are manufactured with precision and care in our state-of-the-art facility located in Xiamen, China. The machined plastic parts we produce undergo a rigorous polishing process for a superior surface finish. With options for shipping by air, sea, or express, we ensure your customized parts are delivered according to your schedule and preferences. Each order is carefully packed in sturdy carton boxes to ensure your parts arrive in perfect condition. Trust ecson for all your custom CNC plastic parts needs.

Support and Services:

Our CNC Machining Plastic Parts come with comprehensive technical support and services to ensure that you can maximize the performance and longevity of your products. Our expert team is well-versed in a variety of CNC machining processes and plastic materials, enabling them to provide you with guidance on the best practices for your specific application.

Technical Support Services Include:

-

Assistance with selecting the appropriate plastic material for your parts based on mechanical requirements, environmental conditions, and budget.

-

Guidance on design optimization for manufacturability to ensure that your parts are designed for efficient and cost-effective production.

-

Consultation on the proper care and maintenance of your CNC machined plastic parts to extend their service life.

-

Troubleshooting support in the event of any performance issues or unexpected results with your parts.

In addition to our technical support, we also offer a variety of services to complement your CNC machining needs:

-

Custom machining services for complex or unique plastic part requirements.

-

Small-batch and high-volume production capabilities to suit your project's scale.

-

Quality assurance processes to ensure that your parts meet stringent standards and specifications.

-

Post-processing services such as surface finishing to enhance the appearance and performance of your machined parts.

We are committed to providing you with exceptional support and service throughout the lifecycle of your CNC machined plastic parts. Our goal is to be your trusted partner in achieving the highest level of precision and quality for your projects.

Packing and Shipping:

Our CNC Machining Plastic Parts are carefully packaged to ensure safe transportation and delivery. Each part is first encased in a protective foam or bubble wrap that conforms to its shape, providing cushioning against impacts. The wrapped parts are then placed into sturdy, corrugated cardboard boxes that are sized appropriately to prevent unnecessary movement during transit.

To prevent any potential damage from environmental factors, we seal the boxes with water-resistant packing tape and, if necessary, each box is lined with a plastic sheet for additional moisture protection. For international shipments or upon request, we can also include desiccants inside the packaging to absorb any condensation that may occur.

Before shipping, each box is labeled with the necessary information, including part numbers, quantity, and handling instructions to ensure that the parts arrive at their destination correctly and without confusion. We use reputable courier services for our deliveries, providing tracking numbers for each shipment so that our customers can monitor the progress of their orders in real time.

We are committed to reducing our environmental impact, so we strive to use recycled materials for our packaging whenever possible and encourage our customers to recycle the packaging materials after they have received their CNC Machining Plastic Parts.

FAQ:

Q1: What types of plastics can be machined using the ecson CNC Machining Plastic Parts service?

A1: The ecson CNC Machining Plastic Parts service is capable of machining a wide variety of plastics, including but not limited to ABS, Polycarbonate, PEEK, Acetal (Delrin), Nylon, and PVC. If you have a specific material in mind, please contact us to confirm its availability and suitability for your project.

Q2: Can ecson provide custom dimensions and tolerances for CNC machined plastic parts?

A2: Yes, ecson specializes in custom CNC machining, which means we can produce plastic parts to your exact dimensions and tolerances. Please provide us with detailed drawings or specifications so we can ensure your parts meet your precise requirements.

Q3: What is the lead time for producing CNC machined plastic parts with ecson?

A3: The lead time for CNC machined plastic parts can vary depending on the complexity of the part, material availability, and current workload. Generally, we aim to complete most projects within 2-4 weeks. For a more accurate estimate, please provide details about your project when you inquire.

Q4: Does ecson support prototype development for CNC machined plastic parts?

A4: Absolutely, ecson is well-equipped to handle prototype development. Our CNC machining service is ideal for creating precise and high-quality prototypes from plastic materials. Feel free to reach out with your prototype requirements to get started.

Q5: How does ecson ensure the quality of the CNC machined plastic parts?

A5: Quality is a top priority at ecson. We perform rigorous quality checks at every stage of the machining process, from material selection to final inspection. Our facility adheres to strict quality control standards to ensure that every part we produce meets or exceeds customer expectations.