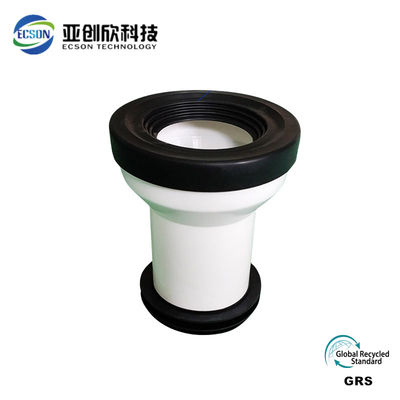

Mould Cavity Single Cavity Plastic Injection Molding For Blow Off Pipe

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mould Life | 100K-1000K Shots | Color | White, Black |

|---|---|---|---|

| Runner System | Hot Runner And Cold Runner | Product Name | Plastic Injection Molding Assembly |

| Mould Cavity | Single Cavity, Multi-cavity | Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| High Light | Single Cavity Plastic Injection Molding,Blow Off Pipe Plastic Injection Molding |

||

Product Description:

The Plastic Injection Molding Assembly is a state-of-the-art solution designed for precision manufacturing of plastic parts across various industries. This product brings together advanced technology in plastic molding to ensure efficient production, high-quality output, and a reduction in overall manufacturing costs. With a focus on versatility and durability, the Plastic Injection Molding Assembly caters to a wide range of applications, from small individual components to large-scale production parts.

At the heart of our product is a sophisticated runner system, which includes both Hot Runner and Cold Runner options. The Hot Runner system is favored for its ability to reduce waste and cycle times by keeping the plastic melted within the runner, eliminating the need for runners in the final product. On the other hand, the Cold Runner system is a cost-effective alternative that is simpler to operate and maintain, although it may produce more waste due to the solidification of runners during the process.

The versatility of the Plastic Injection Molding Assembly is further enhanced by its Mould Cavity configurations. Customers can choose between Single Cavity and Multi-cavity molds depending on their production needs. Single Cavity molds are ideal for lower-volume production or when the utmost precision is required for each part. In contrast, Multi-cavity molds offer the advantage of producing multiple parts per cycle, significantly increasing production efficiency and throughput for high-volume orders.

Our injection mold assembly is designed to offer a considerable Mould Life, ranging from 100K to 1000K Shots. This longevity ensures that customers can enjoy extended production runs without the need for frequent mold replacements, thereby saving on tooling costs and minimizing downtime. The robust construction of the molds ensures that they maintain their precision and quality over countless cycles, providing a consistent output throughout their lifespan.

With customization at the forefront of our design, the Plastic Injection Molding Assembly is available in a selection of colors, such as White, Black, Gray, Green, and Blue. This allows for the production of parts that can match or enhance the aesthetic requirements of the final product without the need for additional painting or finishing processes. The color options also facilitate the manufacturing of parts for different industry sectors, including automotive, consumer products, medical devices, and more.

When it comes to injection molding and assembly, our Plastic Injection Molding Assembly with its Hot Runner and Cold Runner systems provides an efficient workflow from the injection of the molten plastic to the final ejection of the solidified part. The seamless integration of the molding and assembly processes reduces handling and increases the speed of production, allowing for a swift turnaround on orders without compromising on quality.

Our commitment to quality extends to the customer service experience. We provide comprehensive support throughout the injection mold assembly process, from initial design consultation to final production. Our technical team is available to assist with any queries and ensure that the assembly is optimized for maximum performance and cost-efficiency.

In conclusion, the Plastic Injection Molding Assembly is an exceptional tool for manufacturers seeking precision, efficiency, and longevity in their plastic part production. With its customizable runner systems, multiple cavity options, extended mold life, and a variety of color choices, this assembly is more than just a product—it is a complete solution for injection molding and assembly needs. The ability to produce high-quality parts consistently, coupled with the reduced need for post-production finishing, makes the Plastic Injection Molding Assembly an indispensable asset to any production line aspiring for excellence.

Features:

- Product Name: Plastic Injection Molding Assembly

- Mould Cavity: Single Cavity, Multi-cavity

- Mould Life: 100K-1000K Shots

- Color: White, Black, Gray, Green, Blue

- Product Drawings: 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures

- Features an advanced injection molding assembly process

- Designed for high efficiency injection molding and assembly applications

- Robust injection mold assembly designed for longevity and repeatability

Technical Parameters:

| Attribute | Details |

|---|---|

| Runner System | Hot Runner And Cold Runner |

| Mould Life | 100K-1000K Shots |

| Mould Cavity | Single Cavity, Multi-cavity |

| Color | White, Black, Gray, Green, Blue |

| Product Name | Plastic Injection Molding Assembly |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

Applications:

The ecson Plastic Injection Molding Assembly , hailing from Xiamen, China, is a versatile component in the manufacturing sector, engineered to facilitate a range of applications across various industries. This product is designed to meet the diverse needs of the modern market with its robust mould life ranging between 100K to 1000K shots, and is available in a spectrum of colors including White, Black, Gray, Green, and Blue to best suit different design requirements.

When considering the application occasions and scenarios for the ecson Plastic Injection Molding Assembly, its utilization is extensive. The product is particularly suited for applications where precision and durability are paramount. For example, in the automotive industry, the injection molding assembly is often used to manufacture complex parts such as dashboards, bumpers, and car lighting systems. The ability to use 2D drawings, 3D drawings, product samples, or the size of multi-angle pictures ensures that the final product meets exact specifications.

In the realm of consumer electronics, the injection molding and assembly process is critical for creating components like phone cases, computer peripherals, and household appliances. The ecson assembly's color variety allows for aesthetic customization, while the single cavity or multi-cavity mould options provide the flexibility for both low and high volume production runs. This adaptability makes it an ideal choice for consumer electronics, where the demand for high-quality, aesthetically pleasing components is consistently strong.

Medical device manufacturers also greatly benefit from the precision and quality of the ecson Plastic Injection Molding Assembly. The injection molding assembly process ensures that products such as surgical tools and diagnostic equipment casings are produced to the highest standards required for medical applications. The impeccable finish and strength are essential for devices that must adhere to strict regulatory standards and endure rigorous sterilization processes.

Additionally, the injection molding and assembly products can be found in the construction of sporting goods, toys, and various household items, highlighting the product's flexibility and strength. The ecson brand guarantees a consistent quality, ensuring that whether the products are exposed to the stresses of a child's playroom or the rigors of an outdoor environment, they maintain their integrity and appearance.

Overall, the ecson Plastic Injection Molding Assembly stands out as an essential component for manufacturers who require high-quality, durable, and aesthetically adaptable parts. With its long mould life, variety of color options, and the ability to cater to both single and multi-cavity moulding needs, this product is well-positioned to serve a multitude of industries with efficiency and reliability.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Mould Cavity: Our plastic injection molding assembly services offer Single Cavity and Multi-cavity options to accommodate a variety of production volumes and applications.

Color: We provide a wide range of colors for our injection molding and assembly products, including White, Black, Gray, Green, and Blue to match your design specifications.

Product Name: Plastic Injection Molding Assembly

Product Drawings: To ensure precise injection molding assembly, we accept 2D Drawings, 3D Drawings, Product Samples, or The Size Of The Multi-angle Pictures.

Runner System: We utilize both Hot Runner And Cold Runner systems in our injection molding assembly process to optimize the manufacturing efficiency and quality of your products.

Support and Services:

Our Plastic Injection Molding Assembly product is supported by a comprehensive technical support and services team dedicated to ensuring that your experience with our product is seamless and efficient. Our team of experts is well-versed in every aspect of the product and is prepared to assist you with any questions or concerns you may encounter.

From installation and setup to troubleshooting and maintenance, our support services are designed to provide you with quick and effective solutions. We understand the importance of minimizing downtime in your operations, and our technical support team is committed to providing prompt responses to your inquiries.

Our services include detailed product manuals, online resources, and a knowledge base filled with frequently asked questions and answers. We also offer guidance on best practices for the operation and care of your Plastic Injection Molding Assembly to ensure optimal performance and longevity.

In the event that you require personalized assistance, our technical support team is ready to provide you with step-by-step instructions and expert advice tailored to your specific needs. We are dedicated to delivering the highest level of customer satisfaction through our technical support and services.

Please note that our technical support and services do not include on-site visits. However, we are fully equipped to handle the majority of issues remotely, ensuring a quick and efficient resolution to your problems.

We are constantly improving our support services to better serve you. If you have any suggestions or feedback, we would love to hear from you as we strive to enhance our customer experience continuously.

Thank you for choosing our Plastic Injection Molding Assembly product. We look forward to supporting your success with our reliable and professional technical support services.

Packing and Shipping:

To ensure the safety and integrity of the Plastic Injection Molding Assembly during transit, the product will be securely packaged using high-quality, durable materials. Each assembly will be individually encased in a protective foam or bubble wrap, which conforms to the shape of the product to prevent movement and potential damage.

Following this, the wrapped assemblies will be placed in sturdy, corrugated cardboard boxes that are designed to withstand the rigors of shipping. The boxes will be sealed with heavy-duty packing tape and clearly labeled with handling instructions to ensure proper care is taken during handling and transport.

For larger orders, the individual boxes may be secured onto pallets and shrink-wrapped to provide additional stability and protection. These pallets will be loaded into the shipping vehicle using appropriate material handling equipment and will be secured to prevent shifting during transportation.

All shipments will include a detailed packing slip and any necessary customs documentation for international orders. The products will be shipped using reliable carriers with options for tracking and insurance to give our customers peace of mind that their order will arrive on time and in perfect condition.

FAQ:

Q1: What materials can be used with ecson Plastic Injection Molding Assembly?

A1: The ecson Plastic Injection Molding Assembly is capable of processing a wide range of thermoplastic materials, including but not limited to ABS, Polycarbonate, Polypropylene, and Nylon. Depending on your project requirements, our team can assist in selecting the appropriate material.

Q2: What industries typically use the ecson Plastic Injection Molding Assembly?

A2: The ecson Plastic Injection Molding Assembly is versatile and can be used across various industries such as automotive, consumer electronics, medical devices, home appliances, and more. Its precision and reliability make it suitable for producing high-quality parts for a multitude of applications.

Q3: Can the ecson Plastic Injection Molding Assembly handle complex part designs?

A3: Yes, our ecson Plastic Injection Molding Assembly is equipped with advanced technology that allows for the production of complex and intricate part designs. We also provide engineering support to ensure your parts meet all necessary specifications.

Q4: What is the typical lead time for a production run using ecson Plastic Injection Molding Assembly?

A4: The lead time for production runs can vary depending on the complexity of the part, the material used, and the quantity required. We strive to provide efficient turnaround times without compromising on quality. For specific lead times, please contact our sales team with your project details.

Q5: Is ecson able to provide post-molding services for the finished plastic parts?

A5: Yes, ecson offers a variety of post-molding services, including assembly, painting, plating, and ultrasonic welding. We aim to provide a comprehensive solution to meet all your plastic part needs from conception to completion.