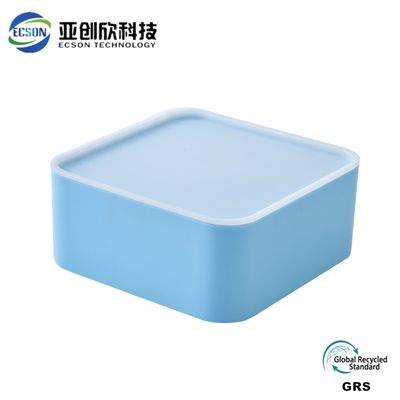

Customized Process Plastic Square Storage Box ISO Cetificate

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Shipping Method | By Air, By Sea, By Express | Lead Time | 7-15 Days |

|---|---|---|---|

| Size | Customized | Color | Customized |

| Tolerance | ±0.01mm | Shape | Customized |

| Application | Industrial | Product Name | CNC Machining Plastic Parts |

| Item Name | Precision Cnc Machining Parts | Supply Type | OEM Service |

| Logo | Accept Custom Logo | Dimension | Customized Per Drawing, Sample |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) | Quality | ISO9001-2000 Certification,High Quality |

| Shipping | Support Express -Sea Freight | Port | Shenzhen |

| Surface Treatment | Polishing | Type | Milling |

| Shape Model | CNC Machining Parts | ||

| High Light | Plastic Square Storage Box ISO,Customized Plastic Square Storage Box |

||

Product Description:

The industrial sector has continually evolved with the integration of advanced technologies that enhance the production and customization of components. Amongst these advancements, CNC (Computer Numerical Control) machining stands out as a pivotal process for manufacturing high-precision parts. Our product, CNC Machining Plastic Parts, is at the forefront of this technological evolution, providing tailored solutions to meet the unique needs of various industrial applications.

CNC Machining Plastic Parts are essential in numerous industries, including aerospace, automotive, medical, and electronics, to name just a few. These custom machined plastic parts are crafted with meticulous attention to detail, ensuring that each piece meets the exact specifications provided by the client. The versatility of CNC technology allows for the creation of complex and intricate designs that would otherwise be difficult to achieve through traditional manufacturing methods.

The product name, CNC Machining Plastic Parts, reflects the specialized process by which these components are produced. CNC machining is a subtractive manufacturing process that uses computer-controlled machines and cutting tools to remove material from a plastic block, shaping it into the desired form. This process is renowned for its precision and repeatability, making it ideal for producing custom machined plastic parts with tight tolerances and superior surface finishes.

One of the most significant advantages of our CNC plastic parts is the ability to customize both color and size according to client specifications. This level of customization ensures that the parts perfectly align with the design and aesthetic requirements of the application they are intended for. Whether the need is for a specific color to match branding elements or a particular size to fit into an existing assembly, our CNC Machining Plastic Parts can be tailored to meet those demands.

The customization process is facilitated by the use of various drawing formats that clients can submit to guide the manufacturing process. We accept a wide range of formats such as CAD, PDF, IGS, STP, and X_T, which enables our team to work with the precise details of the parts to be machined. This compatibility with multiple drawing formats ensures a smooth transition from design to production, minimizing the potential for errors and streamlining the manufacturing process.

The machined plastic parts produced through our CNC machining services exhibit several key characteristics that make them highly sought after in the industrial sector. They are lightweight yet durable, resistant to corrosion, and can be engineered to provide excellent thermal and electrical insulation properties. Additionally, the choice of plastic material can be customized to provide the necessary strength, flexibility, or transparency required by the application.

Our commitment to quality is evident in every aspect of the production process. From the selection of premium raw materials to the employment of skilled technicians and state-of-the-art CNC machinery, we ensure that each batch of CNC plastic parts adheres to the highest standards of quality and performance. Rigorous quality control measures are in place to verify that all dimensions and physical properties of the parts match the client's specifications before they are delivered.

In conclusion, our CNC Machining Plastic Parts represent a confluence of modern manufacturing techniques, customization capabilities, and stringent quality control. These custom machined plastic parts are not only tailored to the specific needs of our clients but are also produced with an emphasis on precision, efficiency, and reliability. Whether for prototyping or large-scale production, these parts are poised to drive innovation and productivity in various industrial applications.

Features:

- Product Name: CNC Machining Plastic Parts

- Surface Finish: Polishing

- Drawing Format: CAD/PDF/IGS/STP/X_T

- Lead Time: 7-15 Days

- Color: Customized

- Shape: Customized

Technical Parameters:

| Parameter | Specification |

|---|---|

| Tolerance | ±0.01mm |

| Shipping Method | By Air, By Sea, By Express |

| Surface Finish | Polishing |

| Application | Industrial |

| Color | Customized |

| Drawing Format | CAD/PDF/IGS/STP/X_T |

| Shape | Customized |

| Product Name | CNC Machining Plastic Parts |

| Material | Plastic |

| Lead Time | 7-15 Days |

Applications:

The brand "ecson" is a notable provider of high-precision CNC machined plastic components, with its origins in the bustling industrial city of Xiamen, China. These premium-quality parts are crafted with an exacting tolerance of ±0.01mm, showcasing the brand's commitment to precision and quality in every product. Designed to meet the diverse needs of the industrial sector, these components are the epitome of customization and reliability.

Ecson's CNC Machining process ensures that each piece is carefully sculpted to the client's specifications, resulting in custom machined plastic parts that are tailored to fit seamlessly into complex machinery and systems. These components are not only functional but also possess an aesthetically pleasing surface finish, thanks to the meticulous polishing that each part undergoes before it is deemed ready for use.

The application occasions and scenarios for ecson's machined plastic components are vast and varied within the industrial realm. They can be found in the automotive industry for lightweight yet durable parts, in medical devices where non-reactive and sterile components are crucial, and in the electronics sector where precision is paramount for the functionality of delicate gadgets. Custom machined plastic parts are also essential in the aerospace industry, where the balance between strength and weight is critical.

Each part is carefully packaged in a carton box to ensure it arrives at its destination in impeccable condition, ready for integration into the client's project. Whether it's a small batch of custom prototypes or a large-scale production run, the attention to detail and quality remains consistent. The versatility of ecson's custom machined plastic parts makes them suitable for use in environments where metal parts may not be ideal due to weight, conductivity, or corrosion concerns.

Ecson's dedication to providing top-tier machined plastic components is evident in every aspect of their product, from the initial design and CNC machining process to the final packing and delivery. Clients seeking a dependable solution for their industrial applications will find that ecson's custom machined plastic parts offer the perfect blend of precision, durability, and customizability, all originating from the advanced manufacturing hub of Xiamen, China.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Drawing Format: CAD/PDF/IGS/STP/X_T

Color: Customized

Surface Finish: Polishing

Lead Time: 7-15 Days

Tolerance: ±0.01mm

At ecson, we specialize in custom CNC plastic parts , offering top-notch custom machined plastic parts services. Our facility in Xiamen, China, is equipped to handle a variety of CAD/PDF/IGS/STP/X_T drawing formats to meet your specific needs. We understand the importance of customization, which is why we provide a range of colors for your custom machined plastic parts . With our precise machining capabilities, we ensure a tolerance of ±0.01mm and a polished surface finish. Trust ecson for your custom CNC plastic parts needs, and we'll deliver within a 7-15 day lead time.

Support and Services:

Our CNC Machining Plastic Parts come with comprehensive technical support and services to ensure maximum satisfaction and performance. Our team of experts is dedicated to providing you with the assistance you need to get the most out of your product. We offer a range of services including troubleshooting, maintenance advice, and guidance on best practices to enhance the longevity and precision of your machined parts.

We understand the importance of minimizing downtime in your operations, which is why we strive to provide quick and efficient solutions to any technical issues you may encounter. Our support services also include detailed documentation and resources that cover the specifications and handling of our CNC machined parts, enabling you to understand the intricacies of the product and its application in your projects.

Please note that our technical support and services are provided under the terms and conditions of the product warranty. We recommend regular checks and adherence to the maintenance schedule for optimal performance of your CNC Machining Plastic Parts. For any issues that are not covered within our documentation, our technical support team is available to offer personalized assistance and advice.

Packing and Shipping:

Our CNC Machining Plastic Parts are carefully packaged to ensure their safe arrival at your destination. Each part is individually wrapped in protective bubble wrap or foam to guard against scratches and impacts during transit. The parts are then securely placed in sturdy, custom-sized cardboard boxes with additional cushioning materials to prevent movement and potential damage. We use moisture-resistant plastic bags for added protection against environmental factors. For larger orders, parts may be grouped and secured on pallets for more efficient handling and shipping. Our packaging process is designed to meet international shipping standards, and we conduct thorough checks to ensure that your products are delivered in perfect condition. We recommend inspecting the packaging upon arrival and reporting any damage immediately for prompt assistance.

FAQ:

Q1: What types of plastic materials can be used with ecson's CNC machining services?

A1: Ecson's CNC machining services can handle a wide variety of plastic materials, including but not limited to ABS, Polycarbonate, POM (Acetal), Nylon, and high-performance plastics like PEEK and Ultem. Please contact us for a complete list of compatible materials.

Q2: What industries typically use ecson's CNC machined plastic parts?

A2: Our CNC machined plastic parts are used across various industries, including aerospace, automotive, medical, electronics, and consumer products. Our precision machining capabilities meet the stringent requirements of each sector.

Q3: Can ecson provide custom CNC machining services for plastic parts?

A3: Absolutely! We specialize in custom CNC machining services. We can work from your CAD drawings or assist you with the design process to produce parts that meet your specific needs.

Q4: What tolerances can ecson achieve with CNC machining of plastic parts?

A4: The tolerances we can achieve with CNC machining vary depending on the material and part complexity. Generally, we can achieve tolerances as tight as +/- 0.005 inches. For specific tolerance requirements, please reach out to us with your project details.

Q5: How does ecson ensure the quality of CNC machined plastic parts?

A5: Quality is a top priority at ecson. We perform rigorous quality control checks at every stage of the production process, from material selection to final inspection. Our facility is equipped with advanced measuring tools and equipment to ensure that every part meets the highest standards of precision and quality.