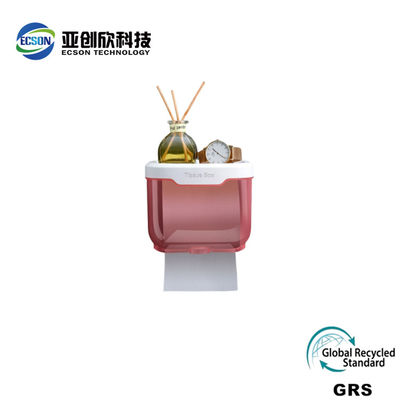

Single Cavity Hot Runner Mould Assembly For Bathroom Tissue Storage Box

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mould Life | 100K-1000K Shots | Color | Customizable |

|---|---|---|---|

| Mould Cavity | Single Cavity, Multi-cavity | Product Name | Plastic Injection Molding Assembly |

| Runner System | Hot Runner And Cold Runner | Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Assembly Type | Fully Assembled | Complexity | Low To Medium |

| Lead Time | Short | Durability | High |

| Precision | High | Production Method | Injection Molding |

| Cost | Competitive | Application | Various Industries |

| Surface Finish | Smooth | Material | Plastic |

| Shape | Customizable | Size | Customizable |

| Production Volume | Large Scale | ||

| High Light | Single Cavity Hot Runner Mould Assembly,Tissue Storage Box Hot Runner Mould Assembly |

||

Single Cavity Injection Mold Assembly For Bathroom Tissue Storage Box

Product Description:

The Plastic Injection Molding Assembly is a state-of-the-art production solution that merges precision engineering with the versatility of plastic molding techniques. This assembly process is designed to cater to a diverse range of industries, including automotive, consumer electronics, medical devices, and many more, providing them with high-quality plastic components that meet stringent specifications and complex geometries. At the heart of this assembly process are the runner systems, which play a crucial role in the injection molding cycle. Our Plastic Injection Molding Assembly offers both Hot Runner and Cold Runner systems, ensuring that clients can select the optimal flow path for their plastic materials according to the specific requirements of their projects.

Hot Runner systems are known for their efficiency in reducing plastic waste, as they maintain the plastic in a molten state throughout the cycle, resulting in faster cycle times and lower costs over time. Conversely, Cold Runner systems are valued for their simplicity and cost-effectiveness in initial setup, making them an excellent choice for simpler or less volume-intensive projects. Our clients have the flexibility to choose the runner system that best aligns with their production needs and budgetary constraints.

To ensure the utmost precision and compatibility with our clients' needs, we accept product drawings in a variety of formats. Our Plastic Injection Molding Assembly process is compatible with 2D Drawings, 3D Drawings, Product Samples, or the Size of Multi-angle Pictures to guarantee that every detail of the design is captured and accurately translated into the final molded part. This meticulous attention to detail ensures that every aspect of the client’s vision is realized to the fullest extent.

The versatility of our Plastic Injection Molding Assembly extends to the customization of the mold cavity as well. With options for both Single Cavity and Multi-cavity molds, our clients can optimize their production based on the volume and complexity of the parts they need. A Single Cavity mold is ideal for large parts or low-volume production, whereas Multi-cavity molds increase production efficiency by allowing multiple parts to be produced in a single cycle, which is particularly beneficial for high-volume orders.

Aesthetic considerations are also paramount in our Plastic Injection Molding Assembly service. As such, we offer a wide range of colors including White, Black, Gray, Green, and Blue to match our clients' specific design and branding requirements. The color consistency is maintained throughout the production run, ensuring that each part exhibits the same hue and saturation, batch after batch.

The injection molding assembly is a complex process that calls for meticulous planning, precise execution, and stringent quality control. Our advanced injection mold assembly techniques ensure that every component is crafted to the highest standards of quality and durability. The end product is a testament to our commitment to excellence in the injection molding assembly process, from the inception of the design to the final production run.

In conclusion, our Plastic Injection Molding Assembly is a comprehensive solution that combines advanced runner systems, versatile mold cavity options, a range of color choices, and compatibility with various product drawings to meet and exceed the expectations of our clients. Whether you are looking to produce intricate parts with complex geometries or high-volume components with consistent quality, our injection molding assembly services are equipped to deliver exceptional results. Our expert team is dedicated to guiding you through every step of the process, ensuring that your project is a resounding success.

Features:

- Product Name: Plastic Injection Molding Assembly

- Product Drawings:

- 2D Drawings

- 3D Drawings

- Product Samples

- Size Of The Multi-angle Pictures

- Mould Life: 100K-1000K Shots

- Runner System:

- Hot Runner

- Cold Runner

- Color:

- White

- Black

- Gray

- Green

- Blue

- Keywords:

- injection molding and assembly

- injection molding assembly

- injection molding and assembly

Technical Parameters:

| Attribute | Details |

|---|---|

| Color | White, Black, Gray, Green, Blue |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Product Name | Plastic Injection Molding Assembly |

| Mould Life | 100K-1000K Shots |

| Mould Cavity | Single Cavity, Multi-cavity |

| Runner System | Hot Runner And Cold Runner |

Applications:

The ecson Plastic Injection Molding Assembly, hailing from the industrial hubs of Xiamen, China, stands as a testament to the precision and quality that modern manufacturing technology can achieve. The product name itself, Plastic Injection Molding Assembly, encompasses a wide array of applications and scenarios where its use is not just beneficial, but essential. The versatility of the injection mold assembly is evident in its ability to produce components in colors such as White, Black, Gray, Green, and Blue, catering to diverse industry requirements and aesthetic preferences.

One of the primary applications of the ecson injection mold assembly is in the automotive industry. The robustness offered by the Mould Life, which ranges from 100K to 1000K Shots, ensures that components such as dashboards, bumpers, and car lighting casings are durable and can withstand the rigors of daily use. The injection molding and assembly process allows for precise and consistent production of parts, which is paramount in the automotive sector where safety and quality cannot be compromised.

In the realm of consumer electronics, the ecson Plastic Injection Molding Assembly provides the scalability to accommodate both Single Cavity and Multi-cavity production demands. This flexibility is crucial for manufacturers who need to rapidly adapt to market trends and product launches, especially when considering the Hot Runner And Cold Runner systems that cater to different production needs and complexities.

Moreover, the medical industry benefits greatly from the high standards of the ecson injection mold assembly. The ability to create complex parts with precision and hygiene in mind is vital for medical devices and equipment. The ecson's products, with their assured quality and longevity, play a pivotal role in the production of life-saving devices, ensuring that they perform reliably over time.

Lastly, the consumer goods sector, which includes products ranging from household items to children's toys, relies on the ecson injection molding and assembly process to deliver high-volume, cost-effective, and aesthetically pleasing products. The diversity in color and the possibility of intricate designs provided by the injection mold assembly process allow manufacturers to meet the ever-changing tastes and preferences of consumers while maintaining a competitive edge in the market.

In conclusion, the ecson Plastic Injection Molding Assembly is a cornerstone of modern manufacturing, offering extensive application occasions and scenarios across various industries. Its origin in Xiamen, China, a city known for its advanced manufacturing capabilities, further underscores the quality and reliability of ecson's injection mold assembly products.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Product Name: Plastic Injection Molding Assembly

Product Drawings: We accept 2D Drawings, 3D Drawings, Product Samples, or provide us with the size of the multi-angle pictures for comprehensive analysis.

Mould Cavity: Options available for Single Cavity or Multi-cavity, depending on your project requirements.

Mould Life: Our molds boast a life range of 100K to 1000K Shots, ensuring durability and longevity.

Runner System: We offer both Hot Runner and Cold Runner systems for the injection mold assembly process.

We specialize in injection molding assembly services, providing high-quality injection molding assembly solutions. Our expertise in injection mold assembly ensures that your product is manufactured to the highest standards. Trust ecson for all your plastic injection molding assembly needs.

Support and Services:

Our Plastic Injection Molding Assembly product is backed by comprehensive technical support and services, designed to ensure that our customers experience seamless operation and maximum productivity with our equipment. Our services include:

Installation Assistance: We provide guidance on proper installation to help you start your production smoothly and efficiently.

User Manuals and Documentation: Each product comes with a detailed user manual and documentation to assist you in understanding the operational aspects and maintenance procedures of our plastic injection molding assemblies.

Training Services: We offer training programs for operators and technicians to ensure they are well-versed in the use of our equipment and can achieve optimal performance.

Preventive Maintenance: Our preventive maintenance services help in prolonging the life of the equipment, minimizing downtime, and keeping it running at peak performance.

Technical Consultation: Our team of experts is available to provide technical advice and to help troubleshoot any issues you might encounter during the operation of our plastic injection molding assembly.

Replacement Parts: We supply a full range of replacement parts that are designed to meet the exact specifications of your equipment, ensuring a perfect fit and function.

Warranty Service: Our products come with a warranty, and we are committed to resolving any covered issues promptly and effectively.

Please refer to the user manual for detailed warranty information and maintenance guidelines. Always follow the recommended safety precautions and operating procedures to ensure the longevity and efficiency of your Plastic Injection Molding Assembly product.

Packing and Shipping:

Product Packaging for Plastic Injection Molding Assembly:

All components of the Plastic Injection Molding Assembly are securely packaged to prevent damage during transit. Each part is individually wrapped in protective bubble wrap and placed within a sturdy, corrugated box with ample cushioning materials. The box is sealed with heavy-duty packing tape to ensure that it remains intact and the contents stay secure.

Shipping for Plastic Injection Molding Assembly:

The packaged Plastic Injection Molding Assembly is shipped using a reliable courier service to provide efficient and safe delivery. The shipment is traceable, with a tracking number provided to the customer upon dispatch. Fragile labels and handling instructions are affixed to the exterior of the box to ensure that the package is treated with care throughout its journey. In the event of special shipping requirements or expedited delivery requests, please contact our customer service team to make arrangements.

FAQ:

Q: What types of plastic materials can be used with the ecson Plastic Injection Molding Assembly?

A: The ecson Plastic Injection Molding Assembly is capable of working with a wide variety of plastic materials, including but not limited to ABS, Polycarbonate, Polyethylene, and Polypropylene. The suitability of material can depend on the specific product design and requirements.

Q: Can the ecson Plastic Injection Molding Assembly handle high-volume production?

A: Yes, the ecson Plastic Injection Molding Assembly is designed for high-volume production runs, ensuring consistency and efficiency in manufacturing processes.

Q: What industries is the ecson Plastic Injection Molding Assembly suitable for?

A: The ecson Plastic Injection Molding Assembly is versatile and can be used across various industries including automotive, medical, consumer goods, and electronics. Its adaptability allows it to meet a wide range of industry standards and requirements.

Q: Are there any customization options available for the ecson Plastic Injection Molding Assembly?

A: Yes, customization options are available. We can tailor the ecson Plastic Injection Molding Assembly to meet specific customer requirements, including but not limited to custom mold designs, material specifications, and product dimensions.

Q: How does the ecson brand ensure the quality of the Plastic Injection Molding Assembly?

A: Quality is a top priority for ecson. We follow strict quality control processes at our Xiamen, China facility, including regular inspections, testing of components, and adherence to industry standards to ensure that every Plastic Injection Molding Assembly meets our high-quality benchmarks.