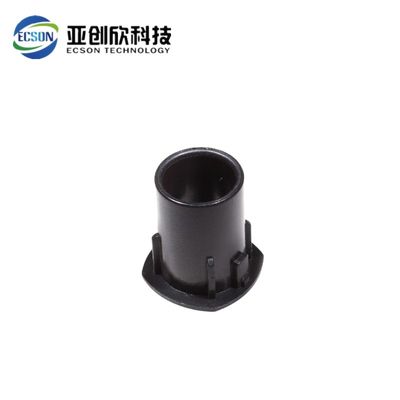

Black Palette Prototype Molding Plastic ODM Precision Injection Molding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Plastic Injection Molding Assembly | Mould Life | 100K-1000K Shots |

|---|---|---|---|

| Color | White, Black, Gray, Green, Blue | Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Mould Cavity | Single Cavity, Multi-cavity | Runner System | Hot Runner And Cold Runner |

| High Light | Black Palette Prototype Molding Plastic,Black Palette Precision Injection Molding,ODM Precision Injection Molding |

||

Plastic Injection Molding Assembly Injection Mold Assembly Black Palette

Product Description:

Plastic Injection Molding Assembly is a process of manufacturing parts by injecting molten plastic into a mold. It is widely used in various industries for creating complex components in a cost-effective manner. This product is created using the latest injection molding technology and can be designed to meet customer needs. It features 2D and 3D drawings, product samples, or the size of the multi-angle pictures. The life expectancy of the mould is between 100K to 1000K shots. The product is available in a variety of colors, including white, black, gray, green, and blue. The plastic injection molding assembly can have single or multi-cavity moulds, which can be customized according to the requirements of the customer. Injection molding and assembly is a reliable and efficient way to create intricate components at a competitive price.

Features:

- Product Name: Plastic Injection Molding Assembly

- Mould Cavity: Single Cavity, Multi-cavity

- Mould Life: 100K-1000K Shots

- Color: White, Black, Gray, Green, Blue

- Product Drawings: 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures

- Injection Molding and Assembly: Expertise and experience in injection molding and assembly, for precise and accurate production.

Technical Parameters:

| Product Name | Technical Parameter |

|---|---|

| Plastic Injection Molding Assembly | Color: White, Black, Gray, Green, Blue Product Drawings: 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures Mould Life: 100K-1000K Shots Runner System: Hot Runner And Cold Runner Mould Cavity: Single Cavity, Multi-cavity |

Applications:

Plastic Injection Molding Assembly, manufactured by ecson, is an effective solution for diverse industrial applications. It is made from high-quality plastic materials that are sourced from reliable suppliers in Xiamen, China. This injection mold assembly offers a robust construction and superior durability, making it ideal for a wide range of applications. It is available in a variety of colors such as white, black, gray, green, and blue. Additionally, it features a hot runner and cold runner system for precise and reliable molding. Moreover, the mold life of this injection molding assembly is between 100K-1000K shots. With its 2D drawings, 3D drawings, product samples, or multi-angle pictures, this injection mold assembly offers precise product details. Therefore, it is highly suitable for demanding manufacturing processes.

Customization:

ecson provides custom services for Plastic Injection Molding Assembly. Our injection mold assembly has a mould life of 100K-1000K Shots and comes in a variety of colors including White, Black, Gray, Green, and Blue. We have both single cavity and multi-cavity molds, and provide both hot runner and cold runner systems. Our injection molding and assembly services are carried out with the highest quality standards and are backed by our experienced team at our Xiamen, China location.

Support and Services:

We offer technical support and services for Plastic Injection Molding Assembly. Our services range from pre-sale consultation, process design, mold design, manufacturing, assembly, testing, to after-sale service.

Our team of experts can provide consultation on the best injection molding process for your project. We will discuss product design, material selection, and other factors to ensure your project is successful.

We design the injection molding process and develop tooling to meet your project requirements. Our team will optimize the process to ensure your product is manufactured in the most efficient and cost-effective manner.

Our mold designers are experienced in all types of injection molding and can design the tooling to meet your requirements. We use the latest CAD software to ensure your design is optimized for the best possible results.

We manufacture the injection molding tools and assemblies using the latest technologies. We use only the highest quality materials to ensure your product is of the highest quality.

Our experienced assembly team will assemble the injection molding tools and components to your exact specifications. We use the latest methods and techniques to ensure your product is assembled correctly.

We perform a variety of tests on the injection molding tools and components to ensure the product meets all the requirements. We use the latest technologies and techniques to ensure the highest product quality.

We provide after-sale service for all our products. Our team can provide technical support and advice on the use of the product, and can help troubleshoot any issues that may arise.

FAQ:

Q1: What is the brand name of the Plastic Injection Molding Assembly?

A1: The brand name of the Plastic Injection Molding Assembly is ecson.

Q2: Where is the Plastic Injection Molding Assembly manufactured?

A2: The Plastic Injection Molding Assembly is manufactured in Xiamen, China.

Q3: What is the Plastic Injection Molding Assembly used for?

A3: The Plastic Injection Molding Assembly is used to produce parts with precise dimensions and intricate shapes from various thermoplastic and thermosetting plastics.

Q4: What are the advantages of the Plastic Injection Molding Assembly?

A4: The Plastic Injection Molding Assembly offers many advantages, such as low labor costs, high accuracy, and fast production time.

Q5: What types of products can be produced with the Plastic Injection Molding Assembly?

A5: The Plastic Injection Molding Assembly can be used to produce a wide variety of products, such as automotive parts, household appliances, and medical devices.