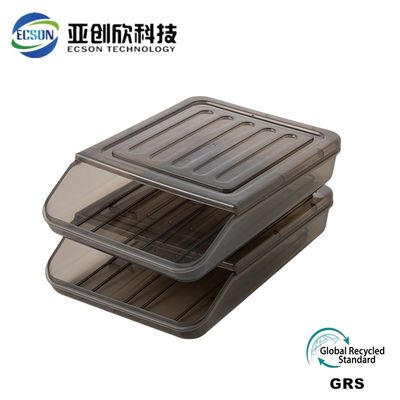

Hot Runner Cold Runner Injection Mold Assembly For Egg Storage Box

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Color | White, Black, Gray, Green, Blue | Product Name | Plastic Injection Molding Assembly |

|---|---|---|---|

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures | Mould Cavity | Single Cavity, Multi-cavity |

| Mould Life | 100K-1000K Shots | Runner System | Hot Runner And Cold Runner |

| High Light | Injection Mold Egg Storage Box,Cold Runner Egg Storage Box |

||

Durable Hot Runner And Cold Runner Injection Mold Assembly For Egg Preservation Box

Product Description:

The Plastic Injection Molding Assembly is a cutting-edge manufacturing solution designed for creating high-quality plastic parts with precision and efficiency. This product is an ideal choice for businesses looking to optimize their production process through the integration of injection molding and assembly. With a robust life expectancy, the mold used in this assembly can deliver between 100,000 to 1,000,000 shots, ensuring a long-term and cost-effective solution for your manufacturing needs.

Our injection mold assembly is versatile in terms of color options providing a range of standard colors including White, Black, Gray, Green, and Blue to match the specific requirements of your products. Custom colors can also be accommodated to align with your brand identity or product design specifications. The aesthetic flexibility offered by our wide color palette ensures that the final products stand out in the market with a professional and appealing look.

At the core of the Plastic Injection Molding Assembly is the sophisticated Runner System . We employ both Hot Runner and Cold Runner systems depending on the project requirements. The Hot Runner system is highly efficient at reducing plastic waste and improving cycle times, making it a cost-effective choice for large-scale production. On the other hand, the Cold Runner system is advantageous for its simplicity and lower initial cost, suitable for smaller runs and simpler part designs.

Understanding the importance of precision, we provide comprehensive support for Product Drawings in various formats. Our team can work from 2D Drawings, 3D Drawings, Product Samples, or The Size Of The Multi-angle Pictures to ensure that the mold precisely captures every aspect of the intended design. This attention to detail guarantees that the injection molding and assembly process results in parts that meet or exceed the expectations for functionality, fit, and appearance.

The Plastic Injection Molding Assembly is equipped with advanced technology and is engineered to handle complex injection molding and assembly tasks with ease. This product is particularly well-suited for industries where high-volume production of plastic parts is required, delivering consistent quality and reliability. Whether your application is in automotive, healthcare, consumer goods, or any other sector, our injection mold assembly is up to the task.

With our Plastic Injection Molding Assembly, you benefit from a streamlined production process that merges the molding and assembling stages into a cohesive workflow. This integration not only saves time but also reduces handling and the potential for errors, resulting in a more efficient and lean manufacturing operation. Our commitment to excellence ensures that every product coming out of the mold meets stringent quality standards, ready for immediate use or further processing.

In conclusion, the Plastic Injection Molding Assembly represents a state-of-the-art solution for your plastic part production. It promises a long mold life, a variety of color options, advanced runner systems, and the ability to work with detailed product drawings for unmatched precision. Whether you're looking to produce simple parts or intricate assemblies, our injection molding and assembly services are designed to deliver the results you need. Experience the benefits of a seamless and productive plastic part production with our superior injection mold assembly.

Features:

- Product Name: Plastic Injection Molding Assembly

- Runner System: Hot Runner and Cold Runner

- Mould Life: 100K-1000K Shots

- Product Drawings: 2D Drawings, 3D Drawings, Product Samples, or The Size of The Multi-angle Pictures

- Color Options: White, Black, Gray, Green, Blue

- Features High Precision Injection Molding and Assembly

- Customizable Injection Molding Assembly Processes

- Integrated Injection Molding and Assembly Services

Technical Parameters:

| Parameter | Description |

|---|---|

| Product Name | Plastic Injection Molding Assembly |

| Color | White, Black, Gray, Green, Blue |

| Mould Cavity | Single Cavity, Multi-cavity |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Runner System | Hot Runner And Cold Runner |

| Mould Life | 100K-1000K Shots |

Applications:

The ecson Plastic Injection Molding Assembly , originating from the technological hub of China Xiamen, represents a pinnacle of precision engineering in the field of injection molding and assembly. This product is tailored to meet a diverse range of application scenarios, where its adaptability and efficiency are of paramount importance. It is a go-to solution for industries requiring high-quality plastic components with a fast turnaround.

One of the key application occasions for the ecson Plastic Injection Molding Assembly is in the automotive industry. Here, both the aesthetic and functional parts of vehicles, such as dashboard panels, light housings, and fluid reservoirs, are crafted with meticulous care. Thanks to the availability of product drawings in 2D and 3D formats, as well as multi-angle pictures and product samples, clients can ensure that components meet their exact specifications, whether they opt for a single cavity or a multi-cavity mold.

Another scenario where the ecson product excels is in the medical field, where the demand for precision and sterility is non-negotiable. Devices such as casings for medical equipment, laboratory equipment components, and housing for medical electronics are produced using the injection molding and assembly process, which guarantees the necessary precision and cleanliness. The choice between a hot runner and cold runner system further allows for customization based on the product requirements, ensuring optimal efficiency and cost-effectiveness.

Consumer electronics is an industry that constantly evolves, necessitating rapid design changes and prototyping. The ecson Plastic Injection Molding Assembly is indispensable here, providing the agility needed to create components for smartphones, laptops, and home appliances. The flexibility in color selection, offering white, black, gray, green, and blue, ensures that the aesthetic requirements of consumer products are easily met.

Moreover, the injection molding and assembly process is integral in the manufacturing of packaging materials. The precision of the ecson assembly product ensures that items such as bottle caps, containers, and other packaging components are produced with the necessary accuracy, durability, and repeatability. Whether a product demands a subtle gray or a vibrant blue, the color customization of the ecson product range accommodates all branding needs.

In conclusion, the ecson Plastic Injection Molding Assembly product is versatile and highly adaptable, suitable for a multitude of industries ranging from automotive and medical to consumer electronics and packaging. Its origin from Xiamen, China, ensures access to cutting-edge technology and a wealth of manufacturing expertise. The availability of various molds, runner systems, and color options makes this product a reliable and efficient choice for high-quality injection molding and assembly requirements.

Customization:

At ecson, we specialize in injection molding and assembly services, offering top-quality Plastic Injection Molding Assembly products tailored to your specific needs. Our factory, located in the industrial hub of China Xiamen, is equipped with cutting-edge technology to ensure precision and efficiency in every product we create.

We understand the importance of customization, and our Plastic Injection Molding Assembly can be manufactured in a variety of colors to match your brand identity or product requirements, including White, Black, Gray, Green, and Blue.

Our experienced team works with Product Drawings in various formats such as 2D Drawings, 3D Drawings, Product Samples, or multi-angle pictures to ensure the exact specifications of your product are met with the utmost accuracy.

The longevity of your product is important to us, which is why our Plastic Injection Molding Assembly products are designed for durability, with a Mould Life of 100K to 1000K shots, ensuring a long-lasting performance.

Whether you need a Single Cavity or Multi-cavity mold, ecson's injection molding assembly services are flexible and customizable to meet the unique demands of your project. Trust us to deliver exceptional quality and service for your injection molding needs.

Support and Services:

Our Plastic Injection Molding Assembly product comes with comprehensive technical support and services designed to ensure your satisfaction and the smooth operation of your assembly system. Our dedicated team of experts is here to provide you with assistance on various aspects of the product, including:

Installation Guidance: Detailed instructions and support for setting up and commissioning your Plastic Injection Molding Assembly to ensure it's operating efficiently and correctly from the start.

User Training: We offer training sessions to help your staff understand and effectively operate the machinery. This includes safety procedures, operation techniques, and maintenance best practices.

Maintenance Support: Information and support on routine maintenance to keep your Plastic Injection Molding Assembly in top condition, reducing downtime and extending the life of your investment.

Troubleshooting Assistance: Quick and responsive help in diagnosing and resolving any operational issues you may encounter, minimizing disruptions to your production process.

Upgrade and Retrofit Services: We provide options for upgrading or retrofitting your system with the latest technology for improved performance and efficiency.

Replacement Parts: A comprehensive inventory of genuine replacement parts is available to ensure your assembly continues to function at its best, with recommendations on spare parts management for your convenience.

Technical Documentation: Access to updated manuals, technical drawings, and other documentation to assist with the understanding and upkeep of your equipment.

Our goal is to provide you with the support you need to achieve optimal performance and reliability from your Plastic Injection Molding Assembly product. For any technical inquiries or service requests, please reach out to our customer service team during regular business hours.

Packing and Shipping:

Product Packaging for Plastic Injection Molding Assembly:

Each Plastic Injection Molding Assembly unit will be individually wrapped in a protective polyethylene film to prevent scratches and damage during handling. The wrapped units will then be carefully placed into custom-designed, corrugated cardboard boxes that are structured to maintain product integrity during transit.

Each box will be sealed with industrial-strength packing tape and labeled with product information, handling instructions, and a barcode for easy inventory management. Fragile stickers will be applied to the exterior of the boxes to ensure careful handling by all shipping carriers.

Shipping for Plastic Injection Molding Assembly:

Products will be shipped using a trusted logistics provider, offering tracking capabilities and insurance for the full value of the Plastic Injection Molding Assembly. Orders will be palletized and shrink-wrapped to maintain stability and prevent movement during transportation.

Our logistics team will conduct a thorough inspection before dispatch to ensure all packages meet our quality standards and are ready for safe transport. We aim for your product to arrive in perfect condition, on time, every time.

FAQ:

Q1: What materials can be used for the ecson Plastic Injection Molding Assembly process?

A1: The ecson Plastic Injection Molding Assembly process can handle a variety of thermoplastic materials, including but not limited to ABS, Polycarbonate, Polyethylene, and Polypropylene. Specific material selection depends on product requirements such as strength, flexibility, and heat resistance.

Q2: What industries typically use ecson Plastic Injection Molding Assembly products?

A2: ecson Plastic Injection Molding Assembly products are used across various industries including automotive, consumer electronics, medical devices, home appliances, and more. The versatility of plastic components makes them ideal for numerous applications.

Q3: Can ecson provide custom mold design services for specific product requirements?

A3: Yes, ecson specializes in custom mold design to meet specific customer requirements. We can assist from the initial concept to the final product design to ensure that the molded parts meet all functional and aesthetic needs.

Q4: How does ecson ensure the quality of the Plastic Injection Molding Assembly products?

A4: ecson adheres to strict quality control procedures throughout the manufacturing process. This includes regular inspections, testing of the molded parts to ensure they meet the necessary specifications, and adherence to industry standards.

Q5: What is the lead time for a typical Plastic Injection Molding Assembly project with ecson?

A5: The lead time for a Plastic Injection Molding Assembly project can vary depending on the complexity of the mold and the quantity of parts required. Generally, after the mold design is approved, production lead times can range from a few weeks to several months. We recommend contacting ecson directly with project specifics for a more accurate timeline.