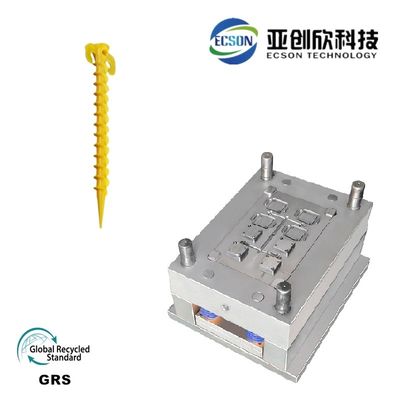

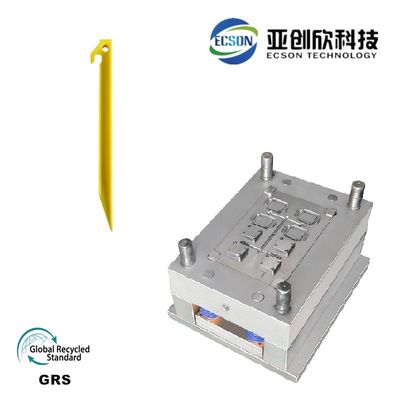

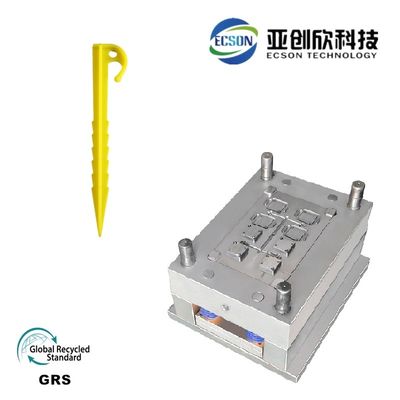

100K-1000K Shots Injection Molding Assembly With Hot Runner

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Runner System | Hot Runner And Cold Runner | Color | White, Black, Gray, Green, Blue |

|---|---|---|---|

| Product Name | Plastic Injection Molding Assembly | Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Mould Cavity | Single Cavity, Multi-cavity | Mould Life | 100K-1000K Shots |

| High Light | 1000K Shots Injection Molding Assembly,Injection Molding Assembly With Hot Runner |

||

100K-1000K Shots Mould Life Plastic Injection Molding Assembly With Hot Runner System

Product Description:

The Plastic Injection Molding Assembly is an advanced manufacturing solution designed to cater to a wide range of industries requiring high-quality plastic parts. With a robust and precise mold life of 100K to 1000K shots, this product stands out in the market for its durability and reliability. The injection molding assembly is critical in producing consistent and accurate plastic components for various applications, ranging from consumer products to intricate automotive components.

One of the key features of the Plastic Injection Molding Assembly is its versatile runner system, which includes both hot runner and cold runner options. The hot runner system is beneficial for reducing waste and improving cycle times by maintaining a molten flow of plastic, while the cold runner system is a cost-effective alternative that can be used for simpler applications where the runner can be easily ejected with the part.

When it comes to mold cavity design, this product offers flexibility with options for a single cavity or multiple cavities. A single cavity mold is ideal for lower volume production and simpler parts, whereas a multi-cavity mold is perfect for high-volume production of identical parts, ensuring consistent quality and reducing manufacturing costs.

The accuracy of the Plastic Injection Molding Assembly is backed by comprehensive product drawings, which include 2D drawings, 3D drawings, product samples, or the size of multi-angle pictures. These detailed representations ensure that every aspect of the part is meticulously planned and executed, resulting in precise dimensions and superior part quality. The availability of detailed drawings and samples aids in streamlining the production process, allowing for rapid prototyping and adjustments before full-scale production commences.

Our injection molding and assembly process is meticulously monitored to guarantee that the final products meet the highest standards of quality. The integrated assembly operations following the molding process enable us to provide complete end-to-end manufacturing solutions. This integrated approach not only saves time and resources but also ensures that the components are engineered to work seamlessly together.

The Plastic Injection Molding Assembly is not just about creating parts; it's about creating solutions that are integral to the functionality and success of your products. With injection molding assembly, customers benefit from a streamlined manufacturing process that combines multiple steps into one cohesive system. This means reduced handling, lower production times, and ultimately, cost savings.

Moreover, the incorporation of injection molding and assembly into a single process has revolutionized the production of plastic parts. This integration leads to greater control over the manufacturing process, allowing for quicker adjustments and enhanced product quality. The close synchronization between the molding and assembly stages results in a more efficient workflow and a reduction in errors, which is critical for maintaining the integrity of the final product.

In conclusion, the Plastic Injection Molding Assembly is a state-of-the-art solution for businesses looking to produce high-quality plastic components with precision and efficiency. With its long mold life, flexible runner systems, and the capability to accommodate both single and multi-cavity molds, this product is tailor-made to address the needs of a diverse client base. Furthermore, the detailed product drawings and integrated assembly process underscore our commitment to delivering exceptional value and performance. Whether you require small or large volumes, intricate designs, or simple parts, the Plastic Injection Molding Assembly is equipped to meet and exceed your manufacturing requirements.

Features:

- Product Name: Plastic Injection Molding Assembly

- Color Options: White, Black, Gray, Green, Blue

- Mould Life: 100K-1000K Shots

- Runner System: Hot Runner and Cold Runner

- Product Drawings Availability: 2D Drawings, 3D Drawings, Product Samples, or Multi-angle Pictures

Technical Parameters:

| Attribute | Details |

|---|---|

| Product Name | Plastic Injection Molding Assembly |

| Mould Life | 100K-1000K Shots |

| Mould Cavity | Single Cavity, Multi-cavity |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

| Runner System | Hot Runner And Cold Runner |

| Color | White, Black, Gray, Green, Blue |

Applications:

The Plastic Injection Molding Assembly by ecson integrates the precision and efficiency of modern manufacturing techniques, making it indispensable in various industrial and consumer applications. This product, hailing from the technological hub of China Xiamen , ensures high-quality standards and reliable performance in diverse scenarios.

One primary application of the ecson Plastic Injection Molding Assembly is in the automotive industry. Here, it is utilized to create robust and durable components such as dashboards, bumpers, and various internal mechanisms. Given the product's longevity, with a mould life ranging from 100K to 1000K shots , it is an ideal choice for automotive manufacturers who require parts that can withstand the rigors of daily use while maintaining integrity over time.

In the realm of consumer electronics, the injection mold assembly capabilities of the ecson product allow for the precise creation of complex components found in smartphones, laptops, and household appliances. Whether it's intricate casings or internal supports, manufacturers can rely on the provision of detailed 2D drawings, 3D drawings, product samples, or the size of the multi-angle pictures to ensure that the final products meet exact specifications.

Medical device manufacturers also benefit from the advanced features of the injection molding assembly , where the demand for high-precision, sanitary plastic components is paramount. The ecson assembly process, whether utilizing a hot runner or cold runner system , ensures that each part is produced with the utmost accuracy and cleanliness, crucial for medical applications.

Consumer goods, such as toys and kitchenware, often involve the production of multiple variants of a product. The multi-cavity mould capability of the ecson Plastic Injection Molding Assembly ensures that these products can be manufactured at scale without compromising on quality. Conversely, for specialized, low-volume products, the single cavity mould option offers flexibility and cost-effectiveness.

Additionally, the injection molding assembly by ecson is also a staple in the construction industry for the fabrication of items like piping systems and insulation materials. The high mould life expectancy means that construction-grade materials can be produced reliably over long periods, supporting large-scale construction projects with consistent supply.

In conclusion, the ecson Plastic Injection Molding Assembly is a versatile solution that can be tailored to a multitude of product manufacturing scenarios. With its origins in Xiamen, China, and the capability to produce detailed, high-quality plastic components, the ecson assembly system is a valuable asset to industries ranging from automotive to healthcare, consumer electronics to construction, and beyond.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Product Name: Plastic Injection Molding Assembly

Mould Life: 100K-1000K Shots

Color: White, Black, Gray, Green, Blue

Mould Cavity: Single Cavity, Multi-cavity

Product Drawings: We accept 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures

ecson specializes in providing high-quality injection mold assembly services for a variety of applications. Our skilled team ensures precision in injection molding and assembly, delivering durable and reliable components. Whether you need a single cavity or multi-cavity mold, our Plastic Injection Molding Assembly is designed to meet your specific requirements. With a mold life ranging from 100K to 1000K shots, and availability in multiple colors including White, Black, Gray, Green, and Blue, we cater to diverse industry needs. Our production is based in China Xiamen, ensuring that each injection molding and assembly project aligns with top-notch standards.

Support and Services:

Our Plastic Injection Molding Assembly product is designed to deliver top-notch performance and reliability. To ensure you get the most out of your product, we offer a comprehensive technical support and service package. Our support includes access to our online knowledge base, troubleshooting guides, and detailed product documentation. We also provide firmware updates and software tools to keep your assembly system running efficiently.

For any issues that require personal assistance, our dedicated technical support team is available to help you diagnose and resolve any product-related issues. Our experts are well-versed in all aspects of the Plastic Injection Molding Assembly and can provide guidance on best practices and maintenance procedures to extend the life of your equipment.

In addition to troubleshooting and direct support, we offer a range of services to enhance your product experience. This includes optional training programs for your staff, to ensure they are fully equipped to operate and maintain the assembly system effectively. We also provide a variety of maintenance and service plans that can be customized to fit your specific needs, helping to minimize downtime and maintain productivity.

Our commitment to excellence doesn't end with the sale. We stand behind our Plastic Injection Molding Assembly product with a warranty that covers defects in materials and workmanship. For added peace of mind, extended warranties and service contracts are available, offering additional levels of support and service to meet your operational requirements.

Please note that our technical support and services are subject to the terms and conditions outlined in your purchase agreement. We recommend reviewing your agreement for detailed information on service entitlements and support coverage.

We are dedicated to providing you with the support you need to keep your Plastic Injection Molding Assembly operating at peak performance. Our team is committed to ensuring your satisfaction and success with our product.

Packing and Shipping:

The Plastic Injection Molding Assembly product is securely packaged in a robust, impact-resistant plastic container, ensuring the components remain intact during transit. Each container is sealed with tamper-evident packaging to guarantee product authenticity upon delivery.

For shipping, the product is further cushioned with eco-friendly, shock-absorbent material to protect against vibrations and impacts that may occur. The outer shipping box is constructed from high-strength corrugated cardboard, designed to withstand the rigors of transportation while being fully recyclable.

Each package includes a detailed packing slip with product information and handling instructions to ensure proper care is taken when unpacking and using the assembly. The shipping label on the exterior clearly indicates the package contents as 'Plastic Injection Molding Assembly' and includes tracking information for real-time monitoring during shipment.

Prior to dispatch, each shipment is inspected to confirm that the packaging standards meet our quality assurance criteria. Our commitment is to deliver the Plastic Injection Molding Assembly product to you in perfect condition, ready for immediate use in your applications.

FAQ:

Q1: What materials can be used with ecson Plastic Injection Molding Assembly?

A1: ecson Plastic Injection Molding Assembly is compatible with a wide range of thermoplastic materials, including but not limited to ABS, Polycarbonate, Polyethylene, and Polypropylene. Depending on your specific requirements, our team can work with you to determine the best material for your project.

Q2: What industries typically use ecson Plastic Injection Molding Assembly?

A2: Our Plastic Injection Molding Assembly is used across various industries including automotive, consumer electronics, medical devices, home appliances, and many others that require high-quality plastic components.

Q3: Can ecson provide custom mold design services for their Plastic Injection Molding Assembly?

A3: Absolutely, ecson specializes in custom mold design. Our experienced engineers can work with you to develop a mold that meets your exact specifications and ensures optimal performance of your finished product.

Q4: How does ecson ensure the quality of their Plastic Injection Molding Assembly products?

A4: ecson adheres to strict quality control procedures throughout the manufacturing process. This includes rigorous testing of molds and final products to ensure they meet our high standards and your expectations. Our facility in Xiamen, China is equipped with state-of-the-art technology to maintain quality consistency.

Q5: What is the typical lead time for a Plastic Injection Molding Assembly project with ecson?

A5: Lead times can vary depending on the complexity of the mold and the quantity of the order. Generally, the production of a new mold may take several weeks, while subsequent production runs using the mold can be completed more quickly. We strive to meet our clients' timelines and can provide a more accurate estimate upon reviewing your project details.