Plastic Injection Molding Assembly Customizable for Your Business Needs

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Color | Customized | Runner System | Hot Runner And Cold Runner |

|---|---|---|---|

| Product Name | Plastic Injection Molding Assembly | Mould Cavity | Single Cavity, Multi-cavity |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures | Lead Time | Short |

| Application | Manufacturing | Material | Plastic |

| Production Volume | Large | Molding Method | Injection Molding |

| Type | Assembly | Shape | Customized |

| Size | Customized | Quality Control | Strict |

| Weight | Customized | Surface Finish | Polishing |

| Precision | High | Durability | High |

Product Description:

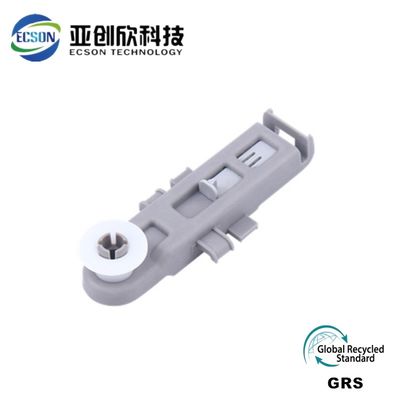

The Plastic Injection Molding Assembly is an advanced manufacturing solution designed to produce high-quality plastic parts in a variety of colors such as White, Black, Gray, Green, and Blue. This product provides versatility and precision through its state-of-the-art injection mold assembly process, which is tailored to meet the specific requirements of each client. The product name itself, Plastic Injection Molding Assembly, signifies the integration of both injection molding and assembly processes to create complex and durable plastic components.

Our assembly product leverages both single cavity and multi-cavity mould options. The single cavity mould is ideal for lower volume production or prototyping, ensuring cost-effectiveness and reduced material usage. On the other hand, the multi-cavity mould is perfect for high-volume production where consistency and uniformity are paramount. Each cavity in the multi-cavity mould is capable of producing an identical part, which greatly enhances the efficiency of the production process.

Accuracy and precision are the hallmarks of the Plastic Injection Molding Assembly, made possible by comprehensive product drawings. We work with 2D Drawings, 3D Drawings, Product Samples, or the Size of Multi-angle Pictures to ensure that every detail of the client's design is meticulously replicated in the final product. The 2D and 3D drawings facilitate a thorough analysis of the product design, allowing for modifications before the actual production begins, ensuring that the final output matches the client's exact specifications.

When it comes to the runner system, our injection molding assembly utilizes both hot runner and cold runner systems, catering to a wide range of product requirements. The hot runner system is designed to reduce waste and cycle times by keeping the plastic molten throughout the injection process. This system is highly efficient for large-scale productions, minimizing the need for secondary processes. Conversely, the cold runner system is often used for simpler or smaller productions where the runner can be cooled and ejected with the part.

Our injection molding and assembly process is optimized for maximum productivity without compromising on quality. The integration of injection molding and assembly operations streamlines the production line, allowing for faster turnaround times and lower costs. The robustness of our injection molding assembly ensures that products are durable, with a high-quality finish that meets or exceeds industry standards.

Each step of the injection molding and assembly process is conducted under strict quality control measures to ensure that the final product is free of defects and meets all functional requirements. Our commitment to quality and customer satisfaction is reflected in our attention to detail throughout the production process, from initial design to final assembly.

In conclusion, the Plastic Injection Molding Assembly is a comprehensive solution for producing plastic parts with exceptional precision and quality. Whether you require small or large volumes, simple or complex designs, our injection molding assembly is equipped to handle your needs. The product's versatility in color, design, and runner systems, combined with our commitment to quality, makes it an ideal choice for manufacturers seeking efficient and reliable plastic part production.

Features:

- Product Name: Plastic Injection Molding Assembly

- Color Options:

- White

- Black

- Gray

- Green

- Blue

- Product Drawings:

- 2D Drawings

- 3D Drawings

- Product Samples

- Size Of The Multi-angle Pictures

- Runner System:

- Hot Runner

- Cold Runner

- Mould Cavity:

- Single Cavity

- Multi-cavity

Technical Parameters:

| Parameter | Specification |

|---|---|

| Product Name | Plastic Injection Molding Assembly |

| Mould Cavity | Single Cavity, Multi-cavity |

| Mould Life | 100K-1000K Shots |

| Color | White, Black, Gray, Green, Blue |

| Runner System | Hot Runner And Cold Runner |

| Product Drawings | 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures |

Applications:

The Plastic Injection Molding Assembly by ecson is a versatile product that has become a staple in various industries due to its efficiency and precision in manufacturing plastic parts. Originating from Xiamen, China , this product is renowned for its robustness and longevity, with a mould life that ranges from 100K to 1000K shots , catering to businesses with high-volume production needs.

Incorporating both hot runner and cold runner systems, the ecson Plastic Injection Molding Assembly offers flexibility and optimization for different injection molding requirements. The hot runner system is ideal for reducing waste and improving cycle times, making it suitable for large-scale production without compromising the quality of the plastic parts produced. The cold runner system, on the other hand, is cost-effective for short runs and simpler applications, providing a versatile solution for various injection molding and assembly scenarios.

Ecson is committed to meeting the precise needs of its clients, offering product drawings in the form of 2D drawings, 3D drawings, product samples, or the size of multi-angle pictures . This ensures that the Plastic Injection Molding Assembly can be tailored to specific product requirements, making it ideal for custom injection molding projects.

The flexibility of the mould cavity design, which ranges from a single cavity to multi-cavity , provides scalability for the injection molding assembly process. This allows for the efficient production of a single prototype or mass production of parts, supporting a wide array of application occasions and scenarios. Whether for automotive components, medical devices, consumer electronics, or home appliances, the ecson Plastic Injection Molding Assembly is engineered to deliver high-quality results.

In the realm of injection molding and assembly , this product stands out for its application in scenarios where precision, repeatability, and speed are paramount. It is particularly beneficial in the production of complex parts that require intricate details and tight tolerances. Moreover, the assembly feature of this product streamlines the manufacturing process, enabling the assembly of various components into a final product in an efficient and cost-effective manner.

To summarize, the ecson Plastic Injection Molding Assembly product is an indispensable tool for businesses looking to optimize their injection molding and assembly processes. With its robust design, flexible runner systems, and customizable mould cavities, it is poised to serve a wide range of industries with diverse production needs.

Customization:

Brand Name: ecson

Place of Origin: China Xiamen

Mould Cavity: Our plastic injection molding and assembly services offer both Single Cavity and Multi-cavity options to cater to diverse client needs.

Color: Available in a variety of colors including White, Black, Gray, Green, Blue to match your specific design requirements for injection molding assembly products.

Product Name: Plastic Injection Molding Assembly

Product Drawings: We accept 2D Drawings, 3D Drawings, Product Samples, Or The Size Of The Multi-angle Pictures to ensure precision in the injection molding assembly process.

Mould Life: Our molds are designed for longevity, with a mould life ranging from 100K to 1000K Shots, ensuring consistent quality and reliability for your injection molding assembly needs.

Support and Services:

Our Plastic Injection Molding Assembly is designed to deliver high-quality, precision parts for a wide range of applications. To ensure you get the most out of our product, we offer comprehensive technical support and services to address any questions or concerns you may have. Our team of experienced engineers and technicians is available to provide expert advice on the operation, maintenance, and troubleshooting of your plastic injection molding equipment. We are committed to offering solutions that enhance your product's performance and extend its lifespan. Our support services include detailed product documentation, an extensive FAQ section on our website, and troubleshooting guides to help you quickly resolve common issues. For more complex or specific problems, our dedicated support team can provide personalized assistance to ensure your assembly process runs smoothly and efficiently.

Packing and Shipping:

Product Packaging for Plastic Injection Molding Assembly:

Each Plastic Injection Molding Assembly unit is securely packaged within a high-strength corrugated box designed to withstand the rigors of transportation. The assembly is encased in custom-fitted foam inserts that provide cushioning against impacts and vibrations. The box is sealed with industrial-grade tape and labeled with the product information and handling instructions to ensure proper care during shipping.

Shipping for Plastic Injection Molding Assembly:

The packaged Plastic Injection Molding Assembly units are shipped in compliance with international shipping standards. They are palletized and shrink-wrapped for additional security and stability during transit. Each pallet is clearly marked with the necessary shipping information, including the destination address, package count, and tracking number. We use reputable carriers to ensure timely and safe delivery of our products to the destination.

FAQ:

Q1: What materials are available for use with the ecson Plastic Injection Molding Assembly process?

A1: The ecson Plastic Injection Molding Assembly process is compatible with a wide range of thermoplastic materials, including but not limited to ABS, Polycarbonate, Polyethylene, and Polypropylene. We can assist in selecting the best material for your specific application.

Q2: Can the ecson Plastic Injection Molding Assembly handle complex part geometries?

A2: Yes, the ecson Plastic Injection Molding Assembly is equipped to handle complex part geometries thanks to advanced mold design and precision manufacturing capabilities. We can work with you to ensure your parts meet the necessary specifications.

Q3: What is the typical lead time for a custom injection molding project with ecson?

A3: Lead times can vary depending on the complexity of the project and the current production schedule. Generally, you can expect a lead time of 4-6 weeks from the final approval of the mold design to the first production run. We recommend discussing your specific timeline needs with our team to get a more accurate estimate.

Q4: Does ecson offer design support for new plastic injection molding projects?

A4: Absolutely! At ecson, we offer comprehensive design support services to help take your concept from idea to production-ready design. Our experienced engineers can provide feedback on design for manufacturability, material selection, and cost-saving opportunities.

Q5: How does ecson ensure the quality of the Plastic Injection Molding Assembly products?

A5: Quality is paramount at ecson. We employ rigorous quality control procedures throughout the manufacturing process, including regular inspections and testing of molds and finished products. We adhere to strict industry standards to ensure that every part meets your specifications and our high-quality benchmarks.