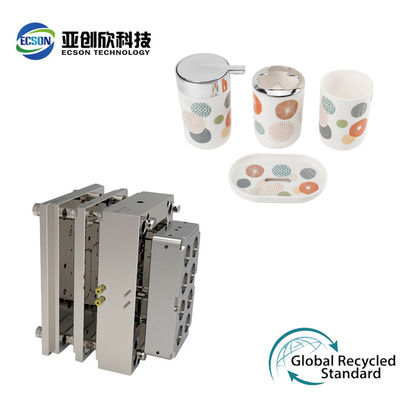

OEM Streamline Bathroom Accessory Set Rapid Plastic Injection Mold

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Service | OEM/ODM | Packaging | Standard Export Carton |

|---|---|---|---|

| Process | Injection Mold Tooling | Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

| PaymentTerm | T/T, L/C, Paypal, Western Union | Color | Transparent,customized Color According Color Pantone |

| Material | Plastic | Function | Automobile, Industry, Garden, Construction, Homeappliance Electronics, Houseware |

| Tooling Lead Time | 2-8 Weeks | Runner | Hot Or Cold |

| Mould Base Material | H50 | Machine | 80-1600T |

| Mold Type | Injection Mold | Number Of Cavity | 2 |

| Cavity Number | Single/Multi | Part Color | Any Color For Plastic Injection Molding |

| Mold Making Process | CNC Machining, EDM, Wire Cutting, Etc. | Cavity Steel | H13 DIN 1.2344 HRC48-52 |

| Part Name | 303593_BGC_2000 Filter Body | Part Material | ABS |

| Product Material | PVC/PP/PC/PU/TPE/TPU/PMMA/ABS,etc | Mould Base | DME,LKM,HASCO,MISUMI,etc |

| High Light | OEM Bathroom Accessory Set,OEM Rapid Plastic Injection Mold,OEM Rapid Plastic Injection Mold |

||

Streamline Bathroom Supplies Mold With Professional Plastic Injection Mold Tooling

Product Description:

The realm of manufacturing has been revolutionized with the advent of plastic injection molds, serving as a cornerstone for mass-producing intricate plastic parts with precision and efficiency. Our Plastic Injection Mold Tooling product stands out in this competitive market, embodying versatility and durability, designed to meet the diverse needs of industries ranging from automotive to consumer electronics. The tooling's adaptability is reflected in the customized hardness and size options we offer, catering to the unique requirements of each project.

Our Plastic Injection Mold Tooling is meticulously crafted using state-of-the-art techniques to ensure a flawless finish. The tooling is characterized by a smooth surface quality that guarantees an excellent finish on the final product. This attention to detail not only enhances the aesthetic appeal of the molded parts but also contributes to their functionality, ensuring that they meet the highest standards of quality and performance.

One of the distinctive features of our injection molding tool is the use of a Standard Export Carton for packaging. This robust packaging solution ensures that the tooling is protected from any potential damage during transit, arriving at your facility in pristine condition. The packaging is designed to withstand the rigors of shipping, providing peace of mind that your investment is safeguarded every step of the way.

The customization options extend to the hardness of the tooling, which can be tailored to suit the specific needs of the molding process and the end-use of the product. Whether your project requires a softer mold for short runs and intricate details or a harder mold for high-volume production and extended life, our injection molding tool can be configured to match your exact specifications. The ability to customize the hardness ensures that you have the right tool for the job, optimizing performance and extending the service life of the tool.

Size customization is another pivotal feature of our plastic injection molds, enabling them to fit a wide array of injection molding machines and accommodate various part sizes. Our team works closely with clients to understand their needs and provide molds that are precisely engineered to their specifications. This customization ensures that the mold fits seamlessly into the production process, maximizing efficiency and reducing the need for costly modifications or adaptations.

In the dynamic world of product design, color plays a vital role in brand identity and consumer perception. Our Plastic Injection Mold Tooling product offers an array of color options, including a transparent finish as well as a spectrum of customized colors according to the Color Pantone system. This flexibility allows for the creation of plastic parts that align perfectly with your design requirements and brand aesthetics, offering limitless possibilities for product differentiation and appeal.

To summarize, our Plastic Injection Mold Tooling product encapsulates the perfect blend of customization, quality, and precision required for the modern injection molding process. With a smooth surface finish, protective packaging, customizable hardness and size, along with a wide range of color options, this tooling solution is crafted to meet the highest standards of the industry. Whether you are producing small, intricate components or large, robust parts, our injection molding tool is the ideal choice for manufacturers seeking reliability, efficiency, and excellence in their plastic injection molding operations.

Streamline Bathroom Supplies Mold With Professional Plastic Injection Mold Tooling

Features:

- Product Name: Plastic Injection Mold Tooling

- Shipping: By Sea, Air, Express

- Surface: Smooth

- Process: Injection Mold Tooling - prototype injection molding

- Size: Customized

- Item: ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory

- Feature: Custom plastic injection molds

- Capability: Production of plastic injection molds

Technical Parameters:

| Attribute | Details |

|---|---|

| Function | Automobile, Industry, Garden, Construction, Home appliance, Electronics, Houseware |

| Process | Injection Mold Tooling |

| Color | Transparent, Customized Color According Color Pantone |

| Service | OEM/ODM |

| Payment Term | T/T, L/C, Paypal, Western Union |

| Packaging | Standard Export Carton |

| Material | Plastic |

| Item | ABS PP PC PE HDPE Nylon Biodegradable Plastic Injection Moulding Factory |

| Hardness | Customized |

| Shipping | By Sea, Air, Express |

Applications:

The ecson brand, originating from China , is renowned for its high-quality Plastic Injection Mold Tooling products, which are indispensable in the manufacturing of plastic components across various industries. With a focus on precision and durability, the ecson tooling process ensures that every product is crafted to meet the highest standards of quality and functionality.

Prototype Injection Molding: In the early stages of product development, ecson 's prototype injection molding services are critical. They allow designers and engineers to create and test parts before full-scale production. This process is especially beneficial in industries such as Automobile and Electronics , where precision is paramount. Prototypes can be used to refine aesthetics and functionality, ensuring the final product is perfect for consumer use.

Custom Plastic Injection Molds: The adaptability of ecson's tooling services is evident in their ability to create custom plastic injection molds tailored to specific customer requirements. Whether it's for Garden equipment, Construction materials, or Homeappliance Electronics , ecson can create molds that fit unique specifications, including intricate designs and complex geometries. This customization extends to the color of the final product, with a range of options from transparent to any customized color according to the Color Pantone system.

The Injection Molding Tool process at ecson uses high-quality plastic materials to ensure that the products are not only aesthetically pleasing but also durable and capable of withstanding the rigors of their intended application. From Houseware items that see daily use to industrial parts that must endure extreme conditions, ecson's tooling products are designed to deliver long-term performance.

When it comes to packaging, the Standard Export Carton employed by ecson guarantees that the molds arrive at their destination in pristine condition, ready for immediate use. This level of care in packaging reflects the brand's commitment to quality and customer satisfaction, making ecson's Plastic Injection Mold Tooling an ideal choice for businesses looking for reliable and efficient manufacturing solutions.

In summary, the versatility of ecson's Plastic Injection Mold Tooling is evident in its application across a multitude of scenarios, from the creation of prototype models to the mass production of custom-designed plastic parts. With its roots in China and a global reach, ecson is a leader in the field of injection molding, offering solutions that serve the diverse needs of the Automobile, Industry, Garden, Construction, Homeappliance Electronics, and Houseware sectors.

Customization:

Brand Name: ecson

Place of Origin: China

Color: Transparent, Customized Color According to Pantone

Surface: Smooth

Size: Customized

Function: Suitable for a wide range of applications including Automobile, Industry, Garden, Construction, Home Appliance, Electronics, and Houseware.

Payment Term: T/T, L/C, Paypal, Western Union

At ecson, we specialize in prototype injection molding and creating custom plastic injection molds tailored to your specific needs. Our expertise in prototype injection molding ensures that we deliver high-quality, precision-engineered products that are customized to your exact requirements. With a commitment to excellence and customer satisfaction, ecson is your trusted partner for all your custom injection molding needs.

Support and Services:

Our Plastic Injection Mold Tooling product comes with comprehensive technical support and services to ensure maximum uptime and peak performance. Our expert team offers guidance on tool design optimization, material selection, and process integration to help you achieve the best results from your tooling investment. We provide detailed documentation and resources to help troubleshoot any issues that may arise during the tooling lifecycle.

We offer a range of services to support your Plastic Injection Mold Tooling needs, including:

- Preventive Maintenance Programs: To extend the life of your tool and ensure it runs efficiently.

- Repair and Refurbishment Services: In the event that your tooling suffers wear or damage, we can restore it to its original condition.

- Training Sessions: To help your staff understand and operate the tooling more effectively, enhancing productivity and reducing downtime.

- Technical Consultation: Our experts are available to provide insights and advice on complex projects or to help overcome specific challenges.

We are dedicated to providing you with the support you need to keep your operations running smoothly. Our technical support team is committed to delivering quick and accurate assistance to ensure the longevity and precision of your Plastic Injection Mold Tooling.

Packing and Shipping:

Our Plastic Injection Mold Tooling is meticulously packaged to ensure its safety and integrity during shipping. Each tool is encased in a protective foam layer that conforms to its unique contours, providing a snug fit and guarding against any movement that could cause damage. This foam is then placed within a sturdy, wooden crate, designed to withstand the rigors of transport. The crate is securely sealed and labeled with all necessary information, including handling instructions and product details, to facilitate a smooth delivery process.

Upon dispatch, the packaged tooling is loaded with care onto our shipping partner's vehicle, ensuring it remains level and stable. We select our logistics partners based on their commitment to handling our products with the utmost care and their proven track record of punctual deliveries. You will receive a tracking number to monitor your shipment's progress until it safely arrives at your destination, ready for immediate use.

FAQ:

Q1: What materials are used in ecson's plastic injection mold tooling?

A1: Ecson uses a variety of high-quality materials for their plastic injection mold tooling, including but not limited to, hardened steel, pre-hardened steel, aluminum, and beryllium-copper, depending on the requirements of the application and the customer's needs.

Q2: Can ecson's plastic injection mold tooling be customized to specific design requirements?

A2: Yes, ecson specializes in customizing plastic injection mold tooling to meet the specific design requirements and specifications provided by the customer. They have the capability to handle complex designs and precision engineering.

Q3: How does the place of origin, China, affect the production of ecson plastic injection mold tooling?

A3: Being located in China allows ecson to leverage advanced manufacturing techniques, cost-effective production, and a skilled workforce, ensuring that their plastic injection mold tooling is both high-quality and competitively priced in the global market.

Q4: What industries can use ecson's plastic injection mold tooling?

A4: Ecson's plastic injection mold tooling is versatile and can be used across a range of industries including automotive, electronics, medical devices, consumer goods, and many more that require high precision and durability in their plastic components.

Q5: How does ecson ensure the quality of their plastic injection mold tooling?

A5: Ecson employs strict quality control processes at every stage of production, from design to manufacturing. They use state-of-the-art machinery and technology to ensure that each mold meets their high standards of quality, precision, and performance.