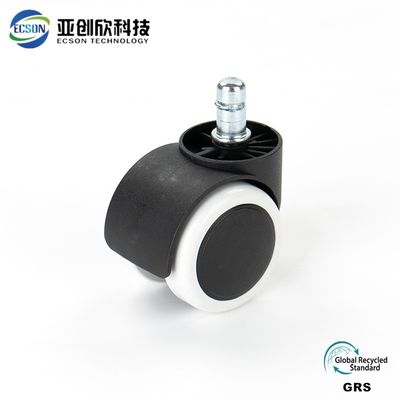

Injection Molded Plastic Parts Molding Customized Office Chair Wheels

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Delivery_time | 15-35 Days | Size | Customized |

|---|---|---|---|

| Shape | Customized | Packing | Carton/wooden Case/pallet |

| Tolerance | ±0.01mm | Runner_type | Cold/hot Runner |

| Molding_type | Injection | Payment_term | T/T, PayPal, Western Union |

| High Light | Plastic Office Chair Wheels,Customized Office Chair Wheels |

||

Product Description:

Our Plastic Injection Molding Parts are a cutting-edge solution designed to meet the intricate needs of modern manufacturing. These parts are created with precision and care, ensuring that each piece meets the highest standards of quality and functionality. With a tolerance of ±0.01mm, our products stand out in the market for their superior accuracy and consistency, making them ideal for applications where precision is paramount. Whether you need components for automotive, medical, electronics, or consumer goods, our Injection Molding Small Parts cater to a broad range of industries with unmatched precision.

We understand that the molding process is critical to the performance of the finished product. That's why we offer both cold and hot runner systems to suit your specific manufacturing requirements. A cold runner system is advantageous for its simplicity and cost-effectiveness, while a hot runner system provides improved efficiency by reducing plastic waste and cycle times. By using the appropriate runner type, our Injection Molding Small Parts can be produced with minimal stress and higher quality, ensuring that the end product performs flawlessly in its application.

To enhance the appearance and longevity of our plastic parts, we apply a meticulous surface treatment process. Polishing is performed to create a smooth and visually appealing finish on each component. This not only improves the aesthetic quality of the parts but also contributes to their functionality by reducing friction and resistance to environmental factors. Our commitment to excellence in surface treatment is just one of the many ways we ensure our Injection Molding Small Parts stand up to the demands of rigorous usage.

In terms of durability, our molds are designed to last. With a mold life ranging from 500,000 to 1,000,000 shots, you can rely on our products for extended production runs without the need for frequent replacements. This longevity translates to cost savings and reduced downtime, allowing you to maintain a competitive edge in your market. The robustness of our molds means that whether you're producing small batches or high volumes, our Injection Molding Small Parts maintain their quality from the first piece to the millionth.

We take great care in packaging our Plastic Injection Molding Parts to ensure they reach you in perfect condition. Depending on your specific needs and the nature of the parts, we offer various packaging options such as carton, wooden case, or pallet. Our carton packaging is ideal for smaller parts or less delicate items, providing a lightweight yet protective covering. For more substantial or sensitive components, wooden cases offer additional security and robustness. When it comes to bulk shipments, pallets are used to ensure stability and ease of handling during transport. No matter the packaging choice, our careful consideration in the packing process guarantees that your Injection Molding Small Parts arrive safe and ready for use.

In summary, our Plastic Injection Molding Parts are the epitome of precision, efficiency, and durability. They are meticulously crafted to meet tight tolerances, equipped with customizable runner systems, finished with high-quality polishing, and designed for an extensive mold life. Packaged with care, they are ready to be incorporated into your manufacturing process, consistently delivering the performance and reliability you need. Trust in our Injection Molding Small Parts to be the small but mighty components that drive your products to success.

Features:

- Product Name: Plastic Injection Molding Parts

- Size: Customized

- Drawing Format: PDF/DWG/IGS/STP/X_T

- Shape: Customized

- Delivery Time: 15-35 Days

- Payment Term: T/T, PayPal, Western Union

- Features: Injection Molding Small Parts

- Features: High Precision Plastic Injection Molding

- Features: Injection Molding Small Parts

Technical Parameters:

| Parameter | Description |

|---|---|

| Cavity Number | Single/multi |

| Mold Life | 500,000-1,000,000 Shots |

| Size | Customized |

| Shape | Customized |

| Molding Type | Injection |

| Packing | Carton/wooden Case/pallet |

| Surface Treatment | Polishing |

| Drawing Format | PDF/DWG/IGS/STP/X_T |

| Payment Term | T/T, PayPal, Western Union |

| Material | Plastic |

Applications:

The ecson brand, originating from China, specializes in the manufacture of Injection Molded Plastic Parts that cater to a wide range of applications and scenarios. These parts are produced with the utmost precision and quality, adhering to certifications such as sgs, fda, and grs, ensuring they meet international standards. The High Precision Plastic Injection Molding process employed by ecson guarantees that every part is crafted with exacting specifications and consistent quality.

With a Minimum Order Quantity of just one and a competitive price of 1000, ecson makes it accessible for businesses of all sizes to benefit from their High Precision Plastic Injection Molding services. The parts are delivered within a timeframe of 25-35 days, packaged securely in wooden cases for molds and offering custom packing for the product, ensuring that they reach the customer in perfect condition.

Ecson's Injection Molded Plastic Parts find their applications in numerous scenarios, including but not limited to, the automotive industry, where high precision and durability are paramount, medical devices that require sterility and compliance with health standards, and consumer electronics where the intricacy of design and reliability are crucial. In addition, the versatility of plastic as a material allows these parts to be used in industries ranging from aerospace to home appliances, where the durability and longevity of the parts are essential.

The company's Supply Ability is a testament to its efficiency and capacity, with the ability to deliver up to 50 sets per month. This is facilitated by customizing the size and cavity number of the molds, offering both single and multi-cavity options, to suit the diverse needs of clients. The material used in the injection molding process is high-grade plastic, ensuring the parts are robust and perform well under various conditions.

Ecson also provides flexible Payment Terms , with a 50% deposit required to initiate the order. Customers can complete payments using various methods such as T/T, PayPal, and Western Union, giving them the convenience to choose as per their preference. The molding type, being injection, is indicative of the efficiency and precision with which ecson operates, making it a reliable choice for clients looking for premium-quality injection molded plastic components.

Customization:

Brand Name: ecson

Place of Origin: China

Certification: sgs, fda, grs

Minimum Order Quantity: 1

Price: 1000

Packaging Details: wooden case for mold, custom packing for product

Delivery Time: 25-35 days

Payment Terms: 50% deposit

Supply Ability: 50 sets/month

Delivery Time: 15-35 Days

Packing: Carton/wooden Case/pallet

Surface Treatment: Polishing

Runner Type: Cold/hot Runner

Size: Customized

Product Description: High Precision Plastic Injection Molding for ecson Injection Molded Plastic Parts, tailored to meet your exact specifications. Manufactured with care in China and meeting stringent certifications such as sgs, fda, and grs, our Injection Molded Plastic Parts represent quality and reliability. With a quick lead time of 15-35 days and flexible payment terms, including a 50% deposit, ecson is ready to supply up to 50 sets per month. Each product is carefully packaged in wooden cases or custom packing solutions, ensuring your parts arrive in pristine condition.

Support and Services:

Our Plastic Injection Molding Parts come with comprehensive technical support and services to ensure you get the most out of our products. Our expert team is dedicated to assisting you with any technical queries or challenges you may encounter. From material selection to part design, tooling, and processing, we provide support across all aspects of plastic injection molding.

We offer a range of services, including on-site support, troubleshooting, process optimization, and maintenance tips to maximize the performance and longevity of your parts. Our proactive approach to technical support is designed to help you prevent issues before they arise, ensuring smooth operation and minimal downtime.

Our technical services also cover training sessions to help your team understand the intricacies of plastic injection molding and how to effectively work with our parts. We believe in empowering our clients with the knowledge to achieve the best possible outcomes from our products.

If you experience any technical difficulties or require assistance, our team is ready to provide prompt and effective solutions. While we exclude contact information in this section, please refer to our contact page or user manual for detailed instructions on how to reach our support team.

Packing and Shipping:

Our Plastic Injection Molding Parts are packaged with utmost care to ensure they arrive at your location in pristine condition. Each part is inspected for quality, securely wrapped in protective film to prevent scratches, and snugly placed in custom-designed, sturdy boxes that fit the parts perfectly, minimizing movement during transit. The boxes are then sealed and labeled according to industry standards, ensuring the package contents are clearly identified.

For shipping, we use reliable courier services with proven track records for handling industrial goods. Packages are stacked on pallets and shrink-wrapped to provide additional stability and security during handling. We also offer the option of tracking your shipment, giving you the peace of mind to monitor your package's journey until it safely reaches your door.

FAQ:

Q1: What brand are the Plastic Injection Molding Parts and where are they manufactured?

A1: The brand name of the Plastic Injection Molding Parts is ecson, and they are manufactured in China.

Q2: What certifications do ecson Plastic Injection Molding Parts come with?

A2: ecson Plastic Injection Molding Parts are certified with sgs, fda, and grs certifications, ensuring quality and safety standards.

Q3: What is the minimum order quantity for ecson Plastic Injection Molding Parts?

A3: The minimum order quantity for our Plastic Injection Molding Parts is 1, making it convenient for businesses of all sizes to place an order.

Q4: How are the Plastic Injection Molding Parts from ecson packaged and what is the price?

A4: The Plastic Injection Molding Parts are packaged in a wooden case for the mould and custom packing for the product. The price for our high-quality parts is set at 1000.

Q5: What are the delivery time, payment terms, and supply ability for the ecson Plastic Injection Molding Parts?

A5: The delivery time for ecson Plastic Injection Molding Parts is 25-35 days. Payment terms require a 50% deposit. We have a supply ability of 50 sets/month to meet your demands.