Polishing Custom Plastic Molding For Modern And Advanced Production

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Color | Customized | Surface Finish | Polishing |

|---|---|---|---|

| Mould Life | 500,000 Shots | Mould Test | 100% Inspection Before Shipment |

| Mould Standard | DME, HASCO, Etc. | Runner System | Cold Runner/Hot Runner |

| Material | Plastic | Cavity Number | Multi-cavity |

| High Light | Modern Custom Plastic Molding,Polishing Custom Plastic Molding |

||

Product Description:

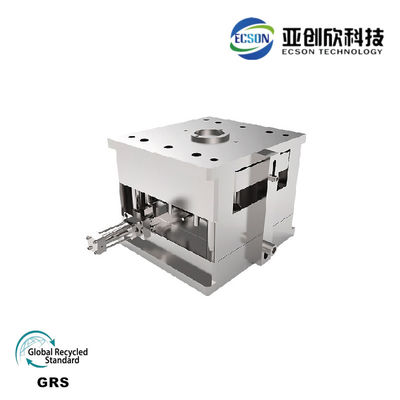

The Home Appliance Mould product is a state-of-the-art solution for manufacturing high-quality air cooler components. Built to withstand the demands of continuous production, this mould is engineered to deliver half a million shots, making it an excellent investment for large-scale manufacturing operations. The robust construction and meticulous design ensure that each air cooler moulding process results in precision parts that meet the highest standards of quality and durability.

With a mould life of 500,000 shots, this product stands out in the industry for its longevity and reliability. It is specifically designed to cater to the production of air cooler parts, ensuring that each creation is flawlessly replicated, maintaining consistency across thousands of produced units. This long-lasting performance is a testament to the quality of materials and craftsmanship that go into the production of this Home Appliance Mould.

The runner system of this mould is versatile, offering both Cold Runner and Hot Runner options. The Cold Runner system is ideal for simpler part designs and materials that are sensitive to heat, while the Hot Runner system is perfect for reducing waste and improving cycle times for more complex or higher volume parts. This flexibility allows manufacturers to choose the most efficient and cost-effective method for their specific air cooler mould production needs, ensuring optimal performance and reduced overhead costs.

Our commitment to meeting our customers' time-sensitive demands is reflected in our lead time of 30-45 days. We understand the importance of timely delivery in the fast-paced world of manufacturing and strive to ensure that your Home Appliance Mould is delivered within this window, without compromising on quality. This prompt lead time ensures that your production schedules stay on track, helping you to maintain a competitive edge in the market.

Quality assurance is paramount, and this is why our Home Appliance Mould product comes with an ISO9001:2015 certification. This globally recognized standard is indicative of our commitment to maintaining the highest level of quality management systems, ensuring that our customers receive a product that not only meets but exceeds industry benchmarks. This certificate is your assurance that the air cooler mould you receive is of the highest quality and produced under stringent quality control processes.

When it comes to designing your air cooler mould, our use of cutting-edge design software such as UG, ProE, and CAD, among others, allows for precision engineering and intricate detail in every mould. Our skilled team of designers is equipped to handle the most complex of designs, ensuring that the final product is in perfect alignment with your requirements. These advanced tools enable us to simulate and analyze the moulding process, making necessary adjustments before the production begins, thus saving time and reducing the likelihood of errors.

In summary, the Home Appliance Mould for air cooler components is an exemplary product that combines durability, efficiency, and precision. It is built to last with a mould life of 500,000 shots, adaptable with both Cold Runner and Hot Runner systems, and is delivered with a quick lead time of 30-45 days. Certified under ISO9001:2015 and designed using the most advanced software, it stands as a testament to our pursuit of excellence in the manufacturing of air cooler moulds. Invest in this Home Appliance Mould today and experience the pinnacle of moulding technology for your air cooler production needs.

Features:

- Product Name: Home Appliance Mould

- Mould Process: Injection Moulding

- Mould Base: LKM, HASCO, Etc.

- Runner System: Cold Runner/Hot Runner

- Size: Customized

- Mould Standard: DME, HASCO, Etc.

- Keywords: air cooler mould, air cooler mould, air cooler mould

Technical Parameters:

| Technical Parameter | Specification |

|---|---|

| Lead Time | 30-45 Days |

| Color | Customized |

| Surface Finish | Polishing |

| Design Software | UG, ProE, CAD, Etc. |

| Mould Base | LKM, HASCO, Etc. |

| Mould Life | 500,000 Shots |

| Runner System | Cold Runner/Hot Runner |

| Size | Customized |

| Mould Standard | DME, HASCO, Etc. |

| Mould Test | 100% Inspection Before Shipment |

Applications:

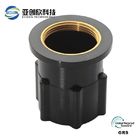

The Ecson Home Appliance Mould is a versatile product that serves as an essential component in the manufacturing of home appliances. Originating from Xiamen, China, this mould is a testament to high-quality engineering and design, with Ecson upholding the rigorous standards of ISO9001:2015 certification. The product is meticulously crafted with a polished surface finish, ensuring a flawless end product for the consumer.

Ecson's Home Appliance Moulds are particularly crucial in the production of air coolers, a staple in homes seeking energy-efficient and cost-effective cooling solutions. The air cooler mould designed by Ecson is engineered to produce parts with precision and consistency, ensuring that each air cooler manufactured meets the highest standards of quality and performance. Whether it's for residential use or commercial spaces, the air cooler mould from Ecson is pivotal in creating products that provide relief during hot weather conditions.

The application occasions for the Ecson Home Appliance Mould are diverse, ranging from small-scale workshops to large industrial manufacturers. The flexibility in the runner system, which includes both Cold Runner and Hot Runner options, allows for customization based on the specific requirements and production capabilities of the manufacturing facility. The air cooler mould can be seamlessly integrated into various production scenarios, from rapid prototyping to full-scale mass production.

Ecson's commitment to flexibility and adaptability is further evidenced by the inclusion of multi-cavity designs, which significantly increase production efficiency. The mould base is compatible with industry-standard systems such as LKM and HASCO, among others, making it a versatile choice for manufacturers with different preferences or existing systems. Such features make the air cooler mould an invaluable asset in the production of high-quality air coolers.

In conclusion, the Ecson Home Appliance Mould, and specifically the air cooler mould , is an indispensable tool in the manufacturing of air cooling units. Its high standards of quality, accredited by ISO9001:2015 certification, combined with a flexible design approach, make it suitable for a wide range of production scenarios. The product's origin from Xiamen, China, assures customers of a mould crafted with attention to detail and a deep understanding of the high-precision requirements of home appliance manufacturing.

Customization:

Brand Name: ecson

Place of Origin: china xiamen

Mould Process: Injection Moulding

Mould Standard: DME, HASCO, Etc.

Runner System: Cold Runner/Hot Runner

Mould Test: 100% Inspection Before Shipment

Surface Finish: Polishing

Our ecson air cooler moulds are expertly crafted at our state-of-the-art facility in china xiamen, utilizing the latest in injection moulding techniques. We adhere to the highest standards, including DME and HASCO, ensuring that each air cooler mould meets our rigorous quality criteria. Whether you prefer a cold runner or hot runner system, we can customize your air cooler mould to suit your specific requirements. Before shipment, every air cooler mould undergoes a thorough 100% inspection to guarantee perfection. Plus, with a polished surface finish, your air cooler mould will not only perform exceptionally but also look sleek and professional.

Support and Services:

Our Product Technical Support for Home Appliance Mould is dedicated to providing you with the necessary assistance to ensure your moulding process is successful and efficient. We offer comprehensive services to address any technical challenges you may face with our mould products. Our support includes troubleshooting, process optimization, and guidance on best practices for maintenance and handling of the moulds to maximize their lifespan and performance.

In addition to reactive support, we offer proactive services to help you achieve the best possible results from our moulds. This includes periodic check-ups, training sessions for your staff on the proper use and care of the moulds, and updates on the latest advancements in mould technology that could benefit your operations.

Please note that our technical support does not include on-site services. However, we are committed to providing you with timely and effective support through various communication channels. Our goal is to ensure that any issue you encounter is resolved quickly, minimizing downtime and helping you maintain a productive and profitable operation.

Packing and Shipping:

The Home Appliance Mould is carefully packaged using robust and secure materials to ensure it reaches you in perfect condition. The mould is first wrapped in a protective layer to prevent any scratches or damages. It is then placed in a sturdy cardboard box that is specifically designed to hold its weight and shape. Reinforcements are added to the package to preserve the integrity of the mould during transportation.

For shipping, the packaged Home Appliance Mould is handled with utmost care. We partner with reliable shipping services that specialize in the safe delivery of industrial products. The mould is shipped with a tracking number that allows you to monitor its journey to your doorstep. Furthermore, the package is insured to protect against any unforeseen events that may occur during transit. Our aim is to provide a seamless delivery experience, ensuring your Home Appliance Mould arrives on time and ready for use.

FAQ:

Q1: What is a Home Appliance Mould?

A1: A Home Appliance Mould is a specialized tool used for manufacturing parts of home appliances through injection molding. It is designed to shape plastic or metal into precise components that are used in the assembly of home appliances like refrigerators, washing machines, air conditioners, and more.

Q2: Can I get a custom mould design for my home appliance component?

A2: Yes, ecson offers custom mould designs based on your specific requirements. You can provide us with the details of the part you need to manufacture, and we can create a mould tailored to your needs.

Q3: What materials are used to make Home Appliance Moulds?

A3: Home Appliance Moulds by ecson are typically made from high-quality steel or aluminum, depending on the requirements of the project and the specific appliance component being manufactured.

Q4: How long does it take to manufacture a mould?

A4: The manufacturing time for a Home Appliance Mould can vary depending on the complexity and size of the mould. Typically, it can take several weeks to a few months. It's best to contact ecson with your project details for a more accurate timeline.

Q5: Is ecson experienced in exporting moulds to other countries?

A5: Yes, ecson is experienced in exporting moulds internationally. With our factory located in Xiamen, China, we have a track record of successfully shipping our moulds to clients across the globe while ensuring they arrive in perfect condition.